dataTaker Universal Logger Keeps Procedures Running Smoothly

As the need for sustainable manufacturing methods in construction increases, companies are utilizing smart monitoring systems to capture and analyze critical data. CAS DataLoggers provided the automated data acquisition solution to bioMASON Inc. in a truly unique process monitoring application.

As the need for sustainable manufacturing methods in construction increases, companies are utilizing smart monitoring systems to capture and analyze critical data. CAS DataLoggers provided the automated data acquisition solution to bioMASON Inc. in a truly unique process monitoring application.

Biotechnology

Founded in 2012 by Founder and CEO Ginger Krieg Dosier, this unique biotechnology start-up manufacturing company harnesses a natural process that will revolutionize the building and construction industry. Their novel technology uses natural bacterial microorganisms and chemical processes to manufacture—or put another way, to grow—durable cement-based bricks and other biocement™-based construction materials. By stimulating bacterial growth, each production run produces bricks that are ‘grown’ much in the same way that coral is naturally grown–in contrast to being ‘fired’ like traditional bricks, with only minimal dependency on natural fossil fuels. In this way, bioMASON enables savings in energy costs, avoids waste in manufacturing, and offers a large reduction of carbon emissions.

The process ferments the bricks with a microorganism that’s naturally evolved to produce a calcium crystal. The team provides the ‘calcite cement’ food. Bacteria grow the cement in a mixing vat onsite kept at ambient temperature, using loose grains of aggregate sand as the raw material. Nutrients and minerals required in the process are obtained from natural, renewable sources, but may also be extracted from industrial waste streams. The bacteria convert the sand into a hard brick form, producing building materials without emitting greenhouse gases and without depleting non-renewable resources.

Process

bioMASON Inc. Chief Technology Officer Michael Dosier explains the process requirements: “Our biological fermentation process occurs at scales too small to see, so naturally our mentality is to measure every one of our process parameters to fully align them with our process. This is an entirely new technology, so in the absence of existing standards, traditional measuring methodologies don’t apply. We’re monitoring anything and everything we can, including facility temperature in several different locations, humidity, pH, and more.

“We’re in the North Carolina triangle so our warehouse facility sees crazy weather, high temperatures, and humidity shifts. To date, we haven’t observed any parameters of concern but we’re exhaustively monitoring each one. Our goal is to make sure that our process is compatible in an industrial context, i.e. for brick and concrete manufacturers.”

Mr. Dosier explains bioMASON’s need for a comprehensive monitoring system: “One of our pH meters is a Mettler-Toledo sensor which monitors pH over a period anywhere from an hour to a day and shows a trend chart of the data. However, we couldn’t pull the data directly from the sensor, so we decided that we needed a standalone monitoring device at that point. We asked ourselves, ‘What if we had one device that could collect data from all of our sensors, that’s standalone?’” To achieve a total process overview, the bioMASON team needed to monitor a whole host of environmental parameters including pH, the ambient temperature of the facility at different points, water temperature, humidity, and more. They began searching for a flexible automated data acquisition system.

Installation

Installation

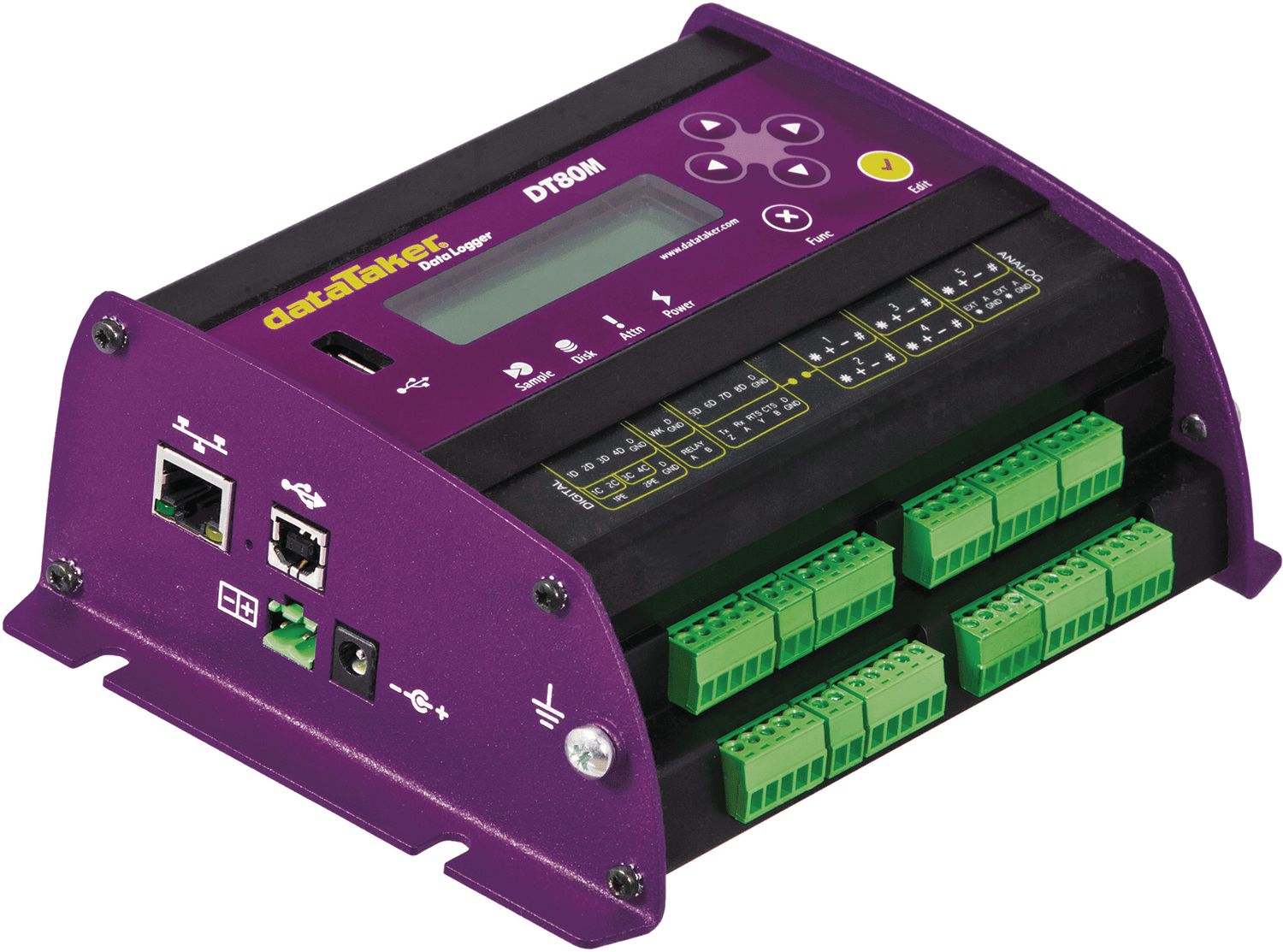

To log and record all these production parameters, CAS DataLoggers supplied bioMASON Inc. with a dataTaker DT80 Universal Data Logger. This automated solution data keeps industrial processes running smoothly in plants and factories. Series 4 dataTaker data loggers feature universal input channels to connect with almost any sensor type. Users can log Temperature, Humidity, Voltage/Current, 4-20mA Loops, Digital, Serial, Resistance, Bridges, Strain Gauges, Frequency, and more—all on one device using one software application.

Usage

The dataTaker DT80 features 5 to 15 Universal Analog sensor inputs to connect with most sensor types and data measurement sources. This ensures that users can log and scale Temperature, Current/Voltage, 4-20mA loops, resistance, pH, humidity, and more. The system uses a dual-channel design allowing up to 10 isolated or 15 common-referenced analog inputs to be used in different combinations.

Right now, the DT80 is located next to one of the facility’s industrial control cabinets, powered by a 120V AC power supply using the included wall adapter. The dataTaker can also operate using the 24V or 12V power supplies located in the cabinet. Meanwhile, dataTaker’s famous durability will provide years of reliable operation even in the harshest industrial environments.

DT80 data loggers are used for local data collection when connected to a PC; for remote monitoring connected to a centralized computer via modem or the internet; or as stand-alone devices. In this application, operators are using the dataTaker in a stand-alone capacity.

Brick Construction

Having demonstrated that it can grow a brick under lab conditions, bioMASON is now building proof-of-concept scalability. To this end, the team is currently performing pilot-scale runs. Data collected during this phase will prove that the technology can reliably produce a viable construction material that’s bespoke-built for construction industry uses.

A typical production run consists of 500 bricks. During each run, the dataTaker automatically triggers its preconfigured logging schedule so users can view and record sensor and environmental data. The latest measurements are shown on the DT80’s integrated display.

Flexible Sensor Connection

As Michael Dosier points out, “The universal nature of the datalogger was the most important feature for us—we knew we wanted to monitor anything and everything. We’ve positioned thermocouples of varying types in different locations, for example, to monitor water temperature and the temperature throughout our facility. The DT80 also logs data from our pH sensor which uses 4-20mA signals on the transmitters. “

“For example, we’re currently using our mix system to trigger the dataTaker to collect data at a sample rate of every 30 seconds. To record another aspect of the process, we might set up the logger to sample every 5 minutes. We can choose to log only when the mixing pump is turned on, or during a certain event occurring in the mix solution. This saves memory space on the logger because we don’t need to record additional data when the mixer’s off. Using the DT80, I log into the database once per run, and every run gets its own data sheet for later analysis.”

Ethernet Communication

In this cutting-edge application, the team needs to protect its proprietary R&D data against corruption but also to secure it against intrusion. Since the dataTaker is operating standalone, i.e. not connected to the facility’s network, users can easily access it on the device’s own Ethernet network. “Data integrity is the most important thing for us as far as communication. The data logger stores all data in CSV format and collates it properly. Ethernet connection was a big point for us, so the data isn’t right there on our network for just anyone to see.” The DT80 also has a built-in serial port (RS232 with modem support) and can communicate over FTP to push data over the Internet or mobile phone network.

For long-term process analysis, Dosier is currently building all this data into a database. “As a starting point, we use Excel for a quick look at the data. For a more in-depth look, we use SAS ‘Jump’ software™ for our core database and for statistical analysis. Previously we used our own database archive to track all performance information.

However, we had to sort and filter the data since our sensors had no triggers to initiate the sampling. It was arduous doing this, so we began using the dataTaker rather than relying on a singular database. Now we’re only logging the data we’re interested in, so everything we see is potentially relevant to our process.”

USB data retrieval was attractive to the team as a secondary consideration. This feature gives them the ability to expand the memory if necessary, without having to purchase proprietary memory modules. While the dataTaker’s large internal memory is enough for their needs so far, they can simply expand the same system in the future.

Software

With the included dataTaker dEX configuration software, users set logging schedules for each sensor, download measurements and analyze historical data. The software is preinstalled on all dataTaker devices and uses a browser-based GUI allowing quick setup and configuration of the logger. The software is configured and runs directly from a web browser and can be accessed anywhere a TCP/IP connection is available. Operators can use any of the logger’s built-in communications ports to view dEX including Ethernet, and USB.

Mr. Dosier is already up and running: “The configuration software is very friendly and useable. The software’s monitoring feature is essential for recording our process, and we get real-time feedback in the form of dashboard mimics. We’re currently running about five different logging schedules (data sets) on the network. We’re using triggers on the schedules so we’re only looking at the data we want. Right now, we have six windows open which we can populate with different feedback values. The software shows us a history chart of sampling over time, and displays trends as tables or onscreen graphs, etc. We haven’t found a performance limit yet but we’re always checking.”

Benefits

The dataTaker DT80 allows bioMASON to cut costs and time otherwise spent manually retrieving data and from having to purchase several different systems with different software. The DT80’s universal inputs connect to every analog sensor in use in this application, automate data collection, and transfer the data over the network via Ethernet—all in a single system. Meanwhile, the software’s mimic display tracks all these parameters at every point of interest in the process, made possible by the dataTaker’s trigger function and large internal memory. All these features are extremely cost-effective.

Michael Dosier sums up the system’s role: “The dataTaker is an effective observer that monitors every aspect of our process, then records and displays it. The data logger gives us the ability to sample a wide variety of sensors in different ways to build a total view of environmental performance through statistical analysis. Looking at our system retroactively through real-time data will make our system more robust and documented from start to finish.”

Wayne Porter, Applications Specialist with CAS DataLoggers, comments, “It’s interesting to see our customer using so much of the dataTaker’s feature set, and in such an original application. They’re certainly making the most of the software and quickly integrating the DT80 into their process.”

To learn more about this exciting new technology, you can see bioMASON founder Ginger Krieg Dosier’s acclaimed TED talk on YouTube.

For more information on the dataTaker DT80 Universal Data Logger, automated data acquisition or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.