Closed Loop Control at Speeds of 10-300 kHz

ADwin real-time data acquisition and control systems are commonly used for signal generation and control of hydraulic test stands, electronic control unit (ECU) testing and laser or E-beam systems. An ADwin system can provide extremely high-speed closed loop control at speeds of 10 to 300 kHz.

Control for Hydraulic Test Stands

Hydraulic test stands are employed in several types of applications including materials testing, component R&D, End-of-Line (EOL) Testing, and various product quality/certification tests. The test stand simulates real-world conditions for the part under test, whether it’s a hydraulic pump or a motor, valve, hydraulic cylinder etc. In a common application, hydraulic pumps and motors are tested for multiple parameters.

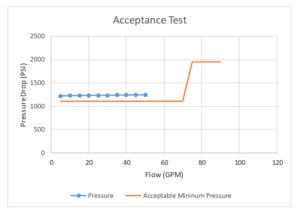

For example, a very common application is end of line test of the operation of a fluid control valve. The manufacturer will establish a pressure/flow performance curve and each part that is shipped must include a document showing that the device has been tested and shown to meet its specifications.

The test bench itself has ports to interface with the device under test including standard tubing or pipe fittings for values or foot or flange mounting plates for motors and pumps. The stand also incorporates sensors for pressure, flow, and temperature. In some cases, electrically controlled servo-hydraulic values provide the ability to regulate flow or pressure electronically, in other cases manual control valves are used.

The precise real-time capabilities of the ADwin system can be used to measure dynamic performance parameters such as the time it takes a valve to open or close, the exact pressure a relief valve opens at or the maximum pressure spike generated when a spool valve goes from an open to a closed position.

Test Bench Examples:

- Hydraulic valve test stands (Directional, Cartridge etc.)

- Hydraulic motor and pump

- Hydraulic hoses

- Hydraulic cylinders

- Fluid nozzles

- Pressure cycle test benches

ADwin for Real-Time Control

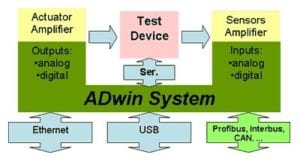

ADwin real-time systems are ideal for intelligent data acquisition and control applications. Utilizing the programmability of the ADwin local CPU, the user can run real-time and/or control programs with fast execution speeds in the kHz to the MHz range.

The ADwin system performs both the control and the stimulation (force-or position-controlled), as well as wave function generation (either numerical or measured). ADwin also performs feedback measurement and analysis.

ADwin PID Benchmarks

- T-11 processor: 20xPID @ 100kHz = Very fast control–a speed of 10-25x is typical.

- T-12 processor: 32xPID @ 300kHz = Extremely high-speed control enabling the most demanding test bench applications.

During the test, ADwin monitors and records data on key values including Pressure, Flow, Displacement, Temperature, etc. ADwin’s onboard DSP processor with its own local memory handles system management, data acquisition, online processing and control of outputs. Processing of each measurement can occur immediately after acquisition.

ADwin-Gold II

ADwin-Gold II

The ADwin Gold-II is an intelligent real-time data acquisition and control system with analog and digital inputs and outputs, counters and a microprocessor with local memory. They are ideal for small-channel (1-2) test applications that require fast DAQ and control in real time under Windows.

Different configurations and expansion modules make these boards cost-effective for application-specific use.

Users can program mathematical operations and functions which are executed immediately after each sampling step even at sampling rates as high as 100 kHz.

ADwin-PRO II

The ADwin-Pro-II is a modular data acquisition system housed in a benchtop or rack-mountable enclosure. Different I/O boards and expansion modules allow the ADwin-Pro-II to be configured for specific uses. Communication with the host PC can be done via Ethernet. Plug-in boards support Analog and Digital I/O, Counter/Timers, PWM signal I/O, Thermocouples and RTD’s, signal conditioning modules, Serial, CAN, and Fieldbus communication.

PRO systems execute mathematical operations and functions immediately even at sampling rates as high as 2 MHz.

Software Benefits

- Intelligent data acquisition with online analysis in real-time along with complex triggering performed at every sampling step.

- Perform mathematical calculations online in the ADwin system including statistics such as peak detection min/max, mean, integral, derivative, correlation, digital filters, FFT, signal analysis, etc.

- Run other functions in addition to data acquisition on the same system including open and closed loop control functions and signal & waveform generation.

For more information on our ADwin Data Acquisition and Control Systems, hydraulic test stands or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.