Affordable Data Acquisition Module Enables Greater Flavor Consistency

CAS DataLoggers supplied the coffee roasting temperature profiling solution to a coffee brewer who makes his own product from his home to sell at local shops and through his website. Creating a good cup of coffee from scratch requires a lot of experimentation, so he sources green coffee beans from many different countries to make original blends. First, the beans are emptied into the roaster and then raised to temperatures up to 204°C (400°F). Afterward, the beans go into the grinder. After establishing a few unique blends, the brewer wanted to document his coffee roasting profiles to give his roasting process repeatability which ensures that the beans had the right taste with every new batch. Working with a limited budget, his business needed a data acquisition product to get an accurate temperature profile of his process, but he couldn’t afford many of the DAQ setups he looked at.

CAS DataLoggers supplied the coffee roasting temperature profiling solution to a coffee brewer who makes his own product from his home to sell at local shops and through his website. Creating a good cup of coffee from scratch requires a lot of experimentation, so he sources green coffee beans from many different countries to make original blends. First, the beans are emptied into the roaster and then raised to temperatures up to 204°C (400°F). Afterward, the beans go into the grinder. After establishing a few unique blends, the brewer wanted to document his coffee roasting profiles to give his roasting process repeatability which ensures that the beans had the right taste with every new batch. Working with a limited budget, his business needed a data acquisition product to get an accurate temperature profile of his process, but he couldn’t afford many of the DAQ setups he looked at.

Installation

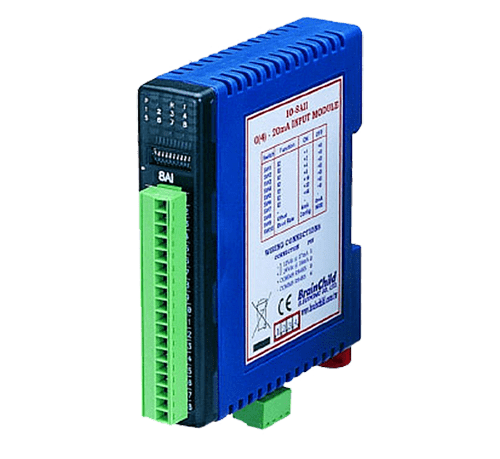

CAS DataLoggers provided him with a Brainchild 6-Channel RTD Input Module which he installed in his brewing room, mounting it on a DIN rail using the included clip. Designed for temperature data acquisition, the Modbus-based module featured analog inputs for 6 RTDs. The removable screw terminal connectors made for quick installation and the module’s small size and light 105g weight made mounting the module a breeze.

The brewer then connected half of the inputs to 3 PT100 RTD temperature sensors which were then placed evenly in the roasting racks. The RTDs record the process temperature at a higher accuracy than would be possible with thermocouples and can maintain temperature stability over several years of use. The module provides direct reading of temperature without the need for scaling and operates on a +12 VDC power supply. Each channel has a connection terminal and an LED status indicator channel. User-set sampling rates from the module log temperature readings from the RTDs in real-time at speeds of up to once every 2 seconds, useful for profiling each roasting cycle.

Usage

The module’s bright LEDs show the status of the inputs/outputs, communication, and power supply. In case the PC were to malfunction, the module’s watchdog timer can identify PC hardware/program errors, sending a signal to put the PC in safe mode, with the timer adjustable from 1 to 255 seconds. This provides a failsafe in case the owner isn’t around to respond in time.

Designed to communicate with a datalogger, PLC, SCADA or HMI via Modbus RTU protocol, the module supports RS485 communication with a baud rate up to 115200 bps. The module was easy to integrate into the user’s network, with his office PC acting as the Modbus master. An RS232 to RS485 converter handles communication between the module and the PC, and the address of the module is set up by using the module’s dip switches (allowing up to 127 addresses).

Designed to communicate with a datalogger, PLC, SCADA or HMI via Modbus RTU protocol, the module supports RS485 communication with a baud rate up to 115200 bps. The module was easy to integrate into the user’s network, with his office PC acting as the Modbus master. An RS232 to RS485 converter handles communication between the module and the PC, and the address of the module is set up by using the module’s dip switches (allowing up to 127 addresses).

All the data is available for real-time viewing and analysis using the standard IO PC Studio Software which produces a temperature curve of the entire process. This helps ensure process repeatability, the most important aspect of his product quality. The DAQ software reads the Modbus registers which contain the data from the sensors. In this way, data is sent to the PC located in his office via serial communication and stored there. The software also enables the brewer to configure the module’s communication settings on the Modbus network, and diagnostic information is also available for troubleshooting. The software is inexpensive and easy to use, so his temperature monitoring project was quickly up and running.

Benefits

Using the data acquisition module to monitor his entire coffee roasting temperature process, the brewer is now able to record all the subtle temperature curves and reproduce them whenever he starts a new roast. By looking at the temperature curves from his office PC, he’s able to monitor process temperatures in the same way used by larger industrial processes (i.e. the leading brands). This guarantees that his coffee always lives up to customer expectations. The module and RTD sensors are an ideal solution for the brewer’s limited budget, giving him maximum data logging reliability and high accuracy. Now he can experiment with new flavors and reproduce his bestsellers to satisfy demand.

For further information on the new Brainchild Modbus modules for data acquisition of many different sensor types, coffee roasting temperature, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.