Continual Monitoring of Gas Turbines is Compact & Cost-Effective

Gas turbine efficiency is critical to a facility’s productivity. A global manufacturer of gas turbines uses Delphin Expert Vibro Data Acquisition & Control Systems for machine vibration analysis of data collected within turbine combustion chambers. Continual monitoring is required not only of conventional vibration data from bearings and shafts but also of dynamic pressure vibrations.

Gas turbine efficiency is critical to a facility’s productivity. A global manufacturer of gas turbines uses Delphin Expert Vibro Data Acquisition & Control Systems for machine vibration analysis of data collected within turbine combustion chambers. Continual monitoring is required not only of conventional vibration data from bearings and shafts but also of dynamic pressure vibrations.

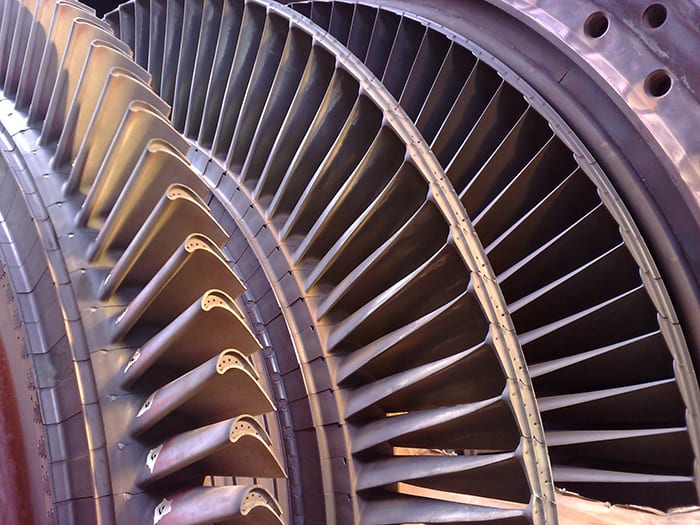

The burning of gas, oil or fuel produces dynamic pressure vibration within combustion chambers and exhaust systems, which is called ‘humming.’ The vibration frequency depends on the particular machine geometry and process parameters. Humming is measured by high-temperature pressure sensors. The pressure vibration data contains information that is relevant to machine performance and parts wear, often indicating problems such as damage or erosion which could eventually lead to a process shutdown.

Installation

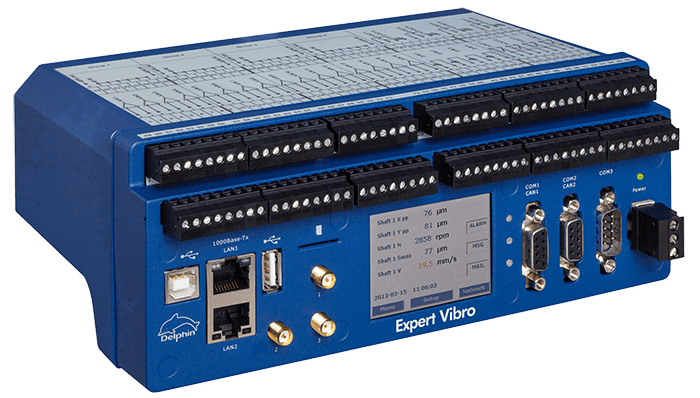

The Expert Vibro is easy to integrate with distributed control systems (DCS) by using ProfiBus or Modbus communication standards. Its compact size allows users to easily install the device in a control cabinet or enclosure, and features 8 or 16 synchronous analog inputs for connection to various sensors such as Eddy current, Acceleration, Velocity or mV/mA signals (pressure, etc).

The Expert Vibro samples at high speed (rates of up to 50kHz per channel) and all channels have galvanic isolation.

The Expert Vibro also features 4 analog and 8 digital outputs for control functionality as well as 4 digital inputs. Delphin has integrated comparators for Keyphasor® sensors enabling flexible triggering, and 24-bit ADC converters allow for high-precision measurements. For added convenience, users can check measurement data and configuration on the touchscreen display.

In this application, three high-temperature-resistant pressure sensors are installed within the turbine combustion chamber and connected to the Expert Vibro which is in a protective cabinet near the test area. These sensors provide dynamic pressure vibrations which are then recorded by the Delphin Expert Vibro device onto its internal 32 GB/1 billion point memory.

Vibration Monitoring Benefits

Now, due to the machine vibration analysis by the Expert Vibro, the turbine manufacturer receives alarm indications whenever their gas turbine bearings and shafts are at risk of damage. Without needing a host PC, the independent Delphin Expert Vibro system also monitors, measures and records the combustion chamber vibration data in real time. Vibration and process data can be viewed in this single system with fully-compatible hardware and software, unlike many other vibration monitoring systems at a higher cost.

The ProfiSignal Vibro software option lets users monitor and analyze the turbine vibration data and visualize the data using FFT (TRMS), cascade, time-signal and orbit diagrams. The Delphin can also be integrated into control systems via Profibus-DP or digital outputs.

Compact and cost-effective, the Delphin system is ideal for many different vibration monitoring applications including turbine shaft vibration, electric motor bearing vibration, and many more. As North American master distributor for Delphin, CAS DataLoggers can supply you with these types of cutting-edge data acquisition systems for any application.

Advanced Software for Visualization Calculations

Delphin’s advanced Profisignal Software is available in three performance levels and is suitable for simple real-time viewing of data or much more advanced, real-time calculations necessary for condition monitoring applications. While it features sophisticated processing and calculations, it is user-friendly and easy to configure. With built in MODbus and Profibus communication protocols, there also exists options for OPC client and server connections to simplify integration with existing distributed control systems.

For further information on the Delphin Expert Vibro, machine vibration analysis or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.