Data Collection For Fault Detection with Delphin

Plant machinery and processes are usually controlled by PLC systems or industrial PCs. Digital and analog signals undergo complex linking via programmable procedures and algorithms. But what happens when the program fails to function in the desired way, or when sporadic failures and irregular patterns begin to occur? Effective machine fault diagnostics generally require the acquisition of the relevant digital and analog signals in parallel to the controlling systems.

Plant machinery and processes are usually controlled by PLC systems or industrial PCs. Digital and analog signals undergo complex linking via programmable procedures and algorithms. But what happens when the program fails to function in the desired way, or when sporadic failures and irregular patterns begin to occur? Effective machine fault diagnostics generally require the acquisition of the relevant digital and analog signals in parallel to the controlling systems.

This is where Delphin products can provide a much more detailed analysis. These professional measurement systems are capable of fast and parallel sampling of digital and analog signals, thereby detecting errors that would otherwise remain hidden. In combination with the Delphin software’s logic diagrams, the analysis is easy. As Delphin’s North American Master Distributor, CAS DataLoggers offers you these powerful systems to help you get your application quickly started and smoothly implemented.

Data Recorder For Fault Diagnostics

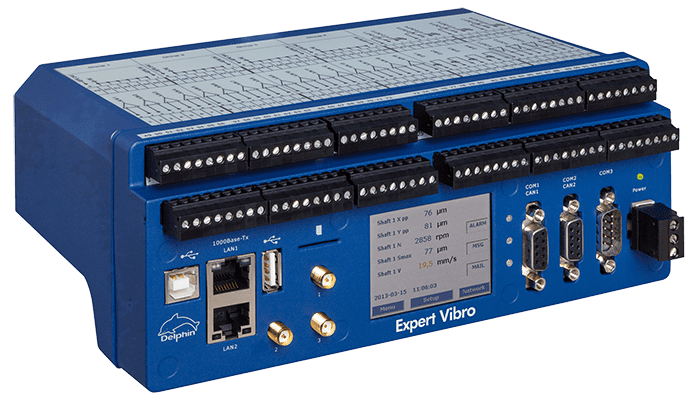

An ideal device for many machine monitoring applications is Delphin’s Expert Transient Data Acquisition System. This new device is able to transmit data to a PC via an Ethernet interface where it can be saved or observed online.

The Expert Transient is especially suited to the evaluation of pressure pulses, fast process monitoring, and controller optimization. The device’s internal storage can be accessed using ProfiSignal Go and the data can be analyzed offline. A signal sequence diagram is especially useful in providing an overview of the chronology of a malfunction event.

The sampling of analog and digital measurement data is performed fully synchronously. The Expert Transient data logger can operate independently for the synchronous acquisition of transient and periodic processes. This enables precise identification of the sequence of events in a malfunction. The system is available in two versions with 8 or 16 synchronous analog inputs and 4 digital inputs and can be further extended if necessary.

The sampling of analog and digital measurement data is performed fully synchronously. The Expert Transient data logger can operate independently for the synchronous acquisition of transient and periodic processes. This enables precise identification of the sequence of events in a malfunction. The system is available in two versions with 8 or 16 synchronous analog inputs and 4 digital inputs and can be further extended if necessary.

Measurement data can be recorded either continuously or according to triggered events. The Expert Transient is based on powerful FPGA technology and is capable of synchronously acquiring and independently saving analog measurement data up to a sampling rate of 50 kHz per channel in combination with digital signals.

Standalone applications without PC support can store up to 16 GB of data in the device’s internal memory. Parallel recording to a high-capacity external NAS device is possible, and the Expert Transient also features an optional Wi-Fi interface.

Application Features

- A parallel synchronous sampling of analog and digital sensors and actuators

- A high-sequenced sampling at µ-second resolution

- Independent fault data acquisition even without PC support

- Relevant and easy-to-follow data evaluation using logic analysis.

Software

Delphin data loggers such as the Expert Transient are paired with the powerful ProfiSignal Go or Basic software which enables recorded signals to be portrayed live in y(t) diagrams. Even large volumes of historical data are easy to analyze using ProfiSignal.

Channels are represented in a clear and intuitive form in a Windows Explorer style, and all measured values can be transferred to online storage on PCs or servers. Visualization and analysis are performed with the ProfiSignal software or OPC Server with any software, providing users with up to 1000x higher time resolution when compared to a typical SCADA system.

The Cutting Edge – Delphin DAQ

Delphin data acquisition systems solve a variety of measurement and control problems in industrial applications. They feature different analog and digital I/O modules that can be used with a wide range of signal types including voltage; 4-20 mA current; thermocouple; RTD; and resistance. Delphin data loggers also offer powerful alarm and programming capabilities allowing them to process measurements and initiate actions on their own.

Delphin systems can be used for local data acquisition and logging when connected to a PC; for remote unattended data collection connected to the internet; or as stand-alone devices.

For further information on the Expert Transient Data Acquisition System, other Delphin products, and machine fault diagnostics, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.