Real-Time Data Acquisition and Control

Test systems are used to determine the dynamic characteristics and parameters of components and sensors. In R&D, these systems acquire not only component parameters but also characteristics of prototypes and pre-production models. Component endurance is determined by testing them over thousands of test cycles. On production lines, test benches ensure a higher level of quality through either random sample or individual component testing (CAQ). Test information and data is then transferred to a control system (PC or programmable controller) via Ethernet or a Fieldbus interface. Users can then store this information as quality records in the production database.

Earlier this year CAS DataLoggers supplied an ADwin Data Acquisition and Control System to a test engineer looking for a data acquisition system which could measure parameters in real time, process the signals and perform fast PID control and provide deterministic real-time response. Since he wanted to get his test application up and running ASAP, he specified a request for simple-to-use visualization software.

Hardware

ADwin test systems are commonly used as test systems for sensors, actuators, control devices, combustion engines, ball bearings, relays, switches, CAN bus devices (e.g. for automotive), and more. The ADwin connects to a PC and performs all of the test functions in real-time. The measurement data is then displayed on the PC through a graphical user interface (GUI). In this way ADwin controls and performs all tests, evaluates the data, and sends results to the quality system.

ADwin hardware features tightly-coupled analog and digital inputs/outputs along with add-ons like counters and bus interfaces which form the connection to the test stand. This allows for extremely low-latency operation and high sampling rates. Online evaluation of measurement data is performed immediately after each sample is taken.

ADwin-Gold System

ADwin-Gold System

Here the chosen system is an ADwin-Gold Real-Time DAQ & Control System, a cost-effective solution for applications requiring few I/O channels and limited expansion or configuration requirements. ADwin applications always run in real-time, and every sampled value or event can be evaluated in the same step. For example, a control function or online analysis is performed immediately after each measurement is sampled.

This is made possible by the ADwin’s design which features a local CPU, additional analog and digital interfaces, and various expansion options. The local CPU is a fast, 32-bit floating-point DSP, equipped with internal memory for executing real-time code and external SDRAM for data. In conjunction with the ADbasic real-time development tool, the DSP allows fast, deterministic program execution with a guaranteed reaction time of less than 1 µs.

For operation with a PC, our customer chose the optional Ethernet interface (10/100 MBit/s). For industrial use with a programmable controller, there are also field bus interfaces such as Profibus, Interbus, CANbus, etc., USB, and serial interfaces.

Working independent of the PC load, ADwin can support multiple controllers simultaneously, using various control algorithms and cycle times. Quick and simple controller development is accomplished using standard control algorithms which can be easily adapted and optimized for specific applications. Open-and closed-loop control functions include PI, PID, cascade, adaptive (e.g. PID speed: max. 500 kHz typically 50-500 kHz).

Measuring the Device Under Test

Using the ADwin Gold system, the engineer first applies an analog stimulus to the Device Under Test (DUT), using multiple channels of actuators. In addition to this stimulation, the response of the components is acquired in real time by reading the ADwin system’s analog input channels. The system immediately calculates how well the test component matches the required specifications. Both stimulation and acquisition can be performed over a very wide range of frequencies, from a few hundred Hertz to several hundred kilohertz. By very precisely timing the stimulation, data acquisition, and online evaluation, the ADwin system accurately calculates the dynamic parameters of the test component.

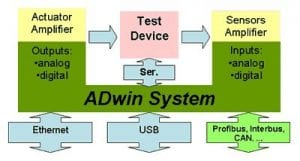

The figure below shows how an ADwin test system is used in a typical system:

Here the ADwin system (shown in green) performs multiple functions:

- Stimulates the DUT via analog and/or digital outputs

- Measures the responses in real-time via analog and/or digital inputs

- Performs an online calculation of the DUT’s dynamic parameters

In this particular test application, test results are displayed on a PC connected via Ethernet.

Visualization Software

The ADwin test system is packaged with a new and innovative visualization software: Kallisté is an object-oriented application development software specifically designed for test engineers working in test and R&D data acquisition applications. With Kallisté users can perform quick data visualization in the form of charts and graphs. Kallisté provides users with visualization for data acquisition, test bench supervision, after-test data analysis, and test reports. Users can run applications under WINDOWS, LINUX, UNIX, MAC OS, and ANDROID.

Being fully intuitive, Kallisté has no icons or programming languages to learn–users design their applications with just English sentences and simple Drag and Drop operations. These features have helped the test engineer to significantly reduce test development time.

Meanwhile, the ADwin software environment is easy to use and runs under Windows (95 through Windows 10) and LINUX or as a reliable stand-alone data acquisition system. ADwin also has drivers for many typical programming environments including VB, VC/C++, TestPoint, LabVIEW MATlab, Simulink and others.

Benefits

ADwin has proven to be a reliable real-time data acquisition and control solution for this test engineer’s application. With its independent DSP, the ADwin Gold provides high-speed reaction times and test data acquisition, control, AND evaluation.

Additionally, the hardware’s Ethernet interface allows for fast data transfer, while Kalliste’s complete WYSIWYG display editor makes it easy to create the measurement application and begin testing.

To learn more about ADwin Data Acquisition and Control Systems, a test system or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or request more information.