Dataloggers Record and Store Product Temperature History

One of the dominant regulatory standards in the Food & Beverage industry, HACCP is the driving force behind food safety procedures in many plants, restaurants and storage facilities. However, personnel are often unsure exactly how to go about testing and monitoring their food product in order to stay in compliance. To help with your facility’s HACCP Plan, CAS DataLoggers can provide your plant, factory or warehouse with Cold Chain dataloggers for full electronic documentation compliance. We’ve provided temperature monitoring systems to cold chain managers, food manufacturers, the FDA, and more. Call us today at (800) 956-4437 to be ready for HACCP!

What Do You Need to Know About HACCP?

HACCP (Hazard analysis and critical control points) is a widely-used food safety standard which places the emphasis on preventing food hazards during and after the production process. This includes preventing biological hazards such as food-borne illnesses. HACCP replaces the previous industry practice of simple inspections of finished products. It covers the entire Food & Bev cold chain from production & preparation to packaging to distribution—AKA ‘farm-to-fork.’

HACCP puts the responsibility on management and personnel to take periodic measurements (usually temperature) of their Food & Beverage products to reduce these risks to a safe level. In the USA, HACCP compliance is regulated by 21 CFR part 120 and 123. Meat HACCP systems are overseen by the USDA, while the FDA oversees seafood and juice.

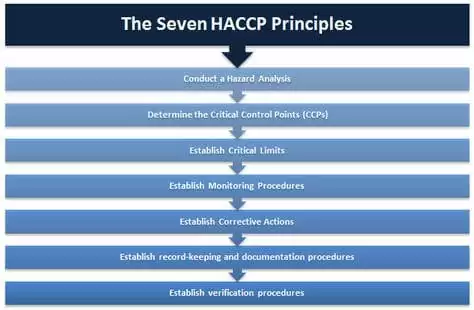

The 7 HACCP Principles:

1. Conduct a Hazard Analysis

In this initial step, facilities identify the specific food safety hazards they may face and also outline the specific preventive actions their personnel can use to control them. Your facility should especially consider food temperatures at each step of the manufacturing process.

2. Determine your Critical Control Points (CCPs)

A Critical Control Point (CCP) is a point or procedure in a food process at which control can be applied and, as a result, a food safety hazard can be prevented or reduced to safe levels. CCPs should consist of all areas where you believe that personnel can act effectively and in a timely manner to address the food safety issues outlined in Step 1.

3. Establish Critical Limits

A critical limit is the maximum or minimum value to which a hazard must be controlled at a CCP to prevent or reduce it to an acceptable level. Commonly, this will be one or more specific temperature ranges for your food product. For this purpose, a Cold Chain Temperature Data Logger is ideal for monitoring and generating alarms on this value.

4. Establish Monitoring Procedures

Continual monitoring is necessary to ensure that your food process is under control at each critical control point. Your plan must list each monitoring procedure and its frequency. Many facilities use data loggers as a low-cost solution to monitor product temperatures and/or environmental levels in storage areas. Most manufacturers offer models for standalone operation, i.e. independent of a PC.

5. Establish Corrective Actions

Corrective actions need to be taken when monitoring indicates a deviation from your established critical limits. Your HACCP plan will identify the corrective actions to be taken if a critical limit is not met. For these events, many of our customers choose a recording device with automated alarm capability.

6. Establish Record-Keeping and Documentation Procedures

HACCP requires that all plants maintain certain documents, including its hazard analysis and written HACCP plan, the monitoring of its CCPs, etc. Data loggers automatically measure and record all data to internal memory or can wirelessly send it to a PC for storage. This way your best practices are electronically documented.

7. Establish Verification Procedures

Your plant is required to validate its own HACCP plan. Validation ensures that your facility’s HACCP plan does what it was designed to do, i.e. if it’s successful in ensuring that your product is produced safely. This can include microbial sampling and analysis, a review of HACCP plans, CCP records, critical limits, etc.

Temperature Data Logger Features:

- Continually monitor the temperature of your product 24/7

- Low-cost and easy to use!

- Ideal for plants, warehouses, restaurants and trucks—every step of the cold chain

- Create electronic documentation proving your regulatory compliance

- Emails you alarms directly to your mobile device!

- Present the temperature data to inspectors in the form of charts and tables.

Get Ready for HACCP!

Make sure your documentation and alarm needs are fully in place so when regulators ask for proof, you’ve got all the data you need. Give the experts at CAS DataLoggers a call at (800) 956-4437 today!