Description

OMK610 Oven Temperature Profiling Kit

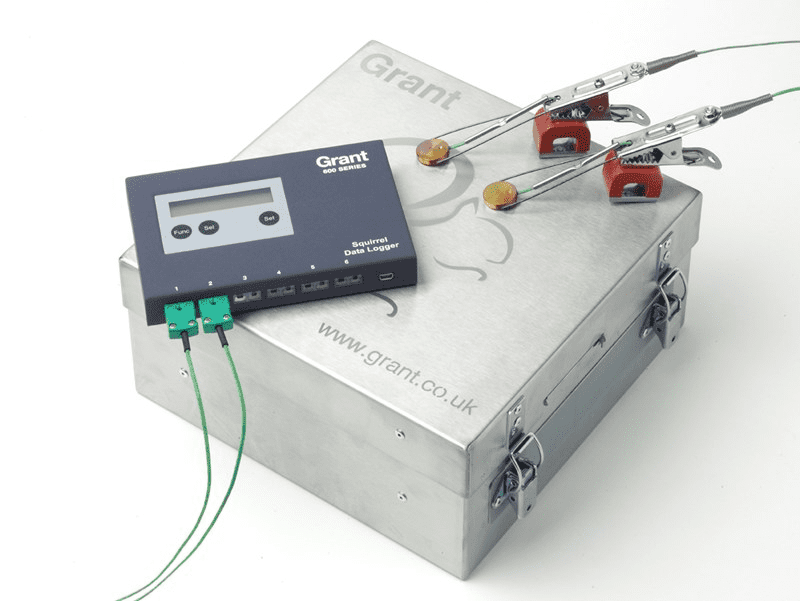

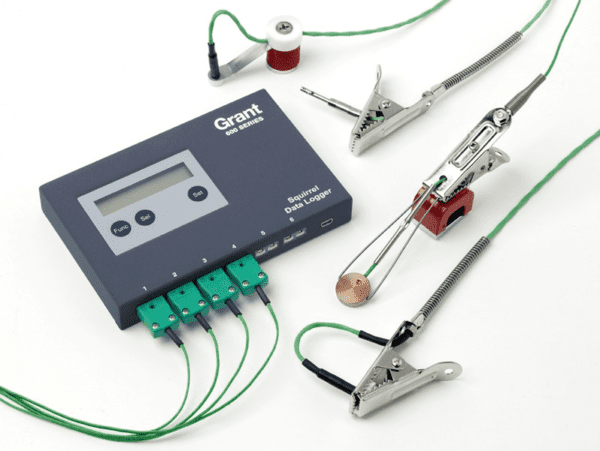

The Grant Instruments OMK610 Oven Temperature Profiling Kit has everything you need for paint oven temperature profiling and paint cure calculations in one easy to use and convenient system. The Oven Temperature Profiling Kit has many new features to assist in production quality control and reducing operating costs.

- Direct report print out from the logger – no PC required in production

- The enhanced thermal barrier that gives maximum protection – available with a heat absorbing insert

- Fast response probes for both air and surface temperature

- PaintView data storage, report generation, and analysis included

- Up to 6 temperature channels, storing up to 250,000 readings

The OMK610 kit contains an OQ610 data logger, PaintView software, thermal barrier, carry case and a quick start guide. A choice of temperature probes is also available.

Benefits of using the OMK610 kit:

- Meets paint manufacturers’ specified cure parameters

- Maintains a specified level of cure ensuring repeatable quality

- Maximises oven usage and throughput

- Optimises oven running (energy) costs

- Archives data and results as part of any quality control system or supplier audit trail

- Line operators can use it without the need for a PC

OMK610 kit comprises of:

- OQ610 data logger

- PaintView software

- Thermal barrier

- Carry case

- Quick start guide

- USB cable

- Set of batteries

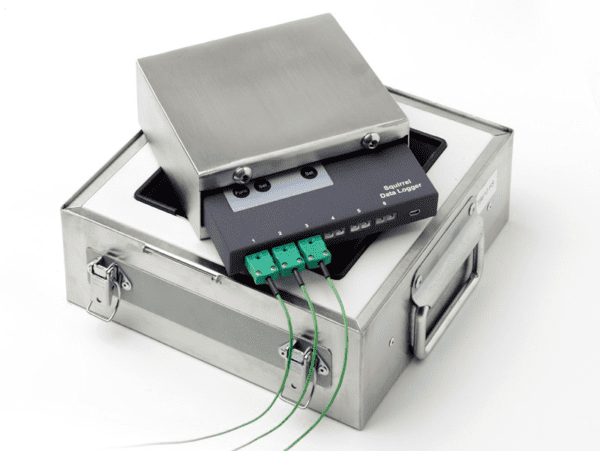

Thermal Barrier

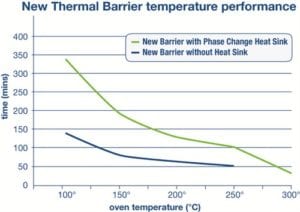

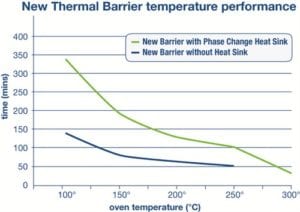

Thermal barriers are insulated containers designed to keep heat out so that the Squirrel data logger inside remains at a safe operation temperature for a specified duration. The oven logger kit comes with a choice of 2 standard thermal barriers with different time/temperature specifications.

Thermal barriers are insulated containers designed to keep heat out so that the Squirrel data logger inside remains at a safe operation temperature for a specified duration. The oven logger kit comes with a choice of 2 standard thermal barriers with different time/temperature specifications.

- Provides protection to Squirrel data loggers when used in high temperature oven profiling applications (static or conveyor)

- Standard models with different performance characteristics compatible with most paint/powder coating applications.

- Made from stainless steel, for years of use

- Custom barriers available for high temperature applications – quoted and manufactured to order

- Can be constructed using special phase change material for added protection.

Software

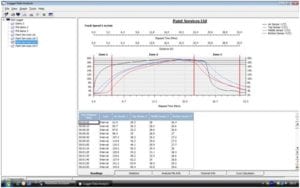

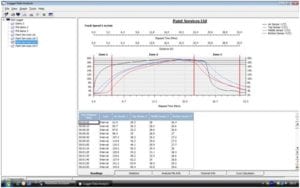

PaintView is an easy-to-use software package designed for exclusive use in the paint and finishing industry and is included free with every OQ610 temperature logger.

PaintView is an easy-to-use software package designed for exclusive use in the paint and finishing industry and is included free with every OQ610 temperature logger.

It enables easy setup of the logger and automatic download of data from the logger into a meaningful measure of paint cure.

For advanced paint cure calculations, it can also provide rapid interpretation of results. PaintView also gives the additional benefits of graphically analyzing historical and on-line data, along with advanced reporting. PaintView can be easily set-up in the minimum amount of time and with the least amount of hassle. With regular usage it can pin-point any uneven temperatures within the stoving process. This will improve the quality of your process, so that fewer faults occur, and helps to avoid costly re-work in the future.

Features:

- Configure the OQ610 logger for all oven applications

- Create paint cure data libraries (by manufacturer and / or paint type)

- Set optimized cure temperature curves with upper and lower limits

- Create graphical and statistical data reports via the Report Wizard, incorporating company logos and JPEG photographs

- 5 user languages are included – English, German, French, Spanish, and Italian

Thermal barriers are insulated containers designed to keep heat out so that the Squirrel data logger inside remains at a safe operation temperature for a specified duration. The oven logger kit comes with a choice of 2 standard thermal barriers with different time/temperature specifications.

Thermal barriers are insulated containers designed to keep heat out so that the Squirrel data logger inside remains at a safe operation temperature for a specified duration. The oven logger kit comes with a choice of 2 standard thermal barriers with different time/temperature specifications.

PaintView is an easy-to-use software package designed for exclusive use in the paint and finishing industry and is included free with every OQ610 temperature logger.

PaintView is an easy-to-use software package designed for exclusive use in the paint and finishing industry and is included free with every OQ610 temperature logger.