Description

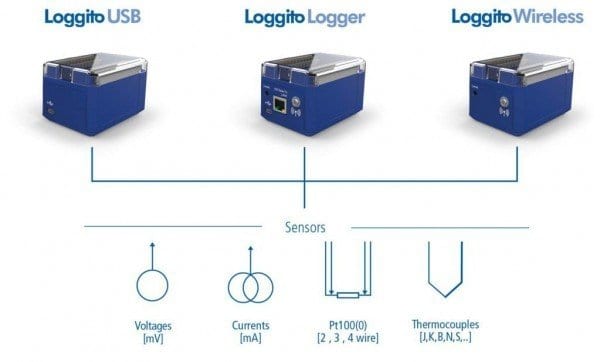

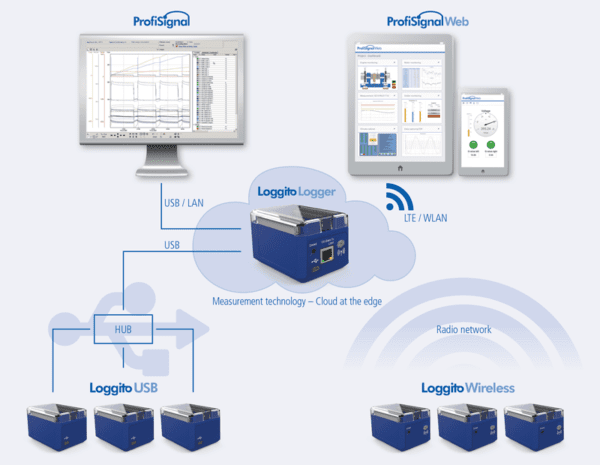

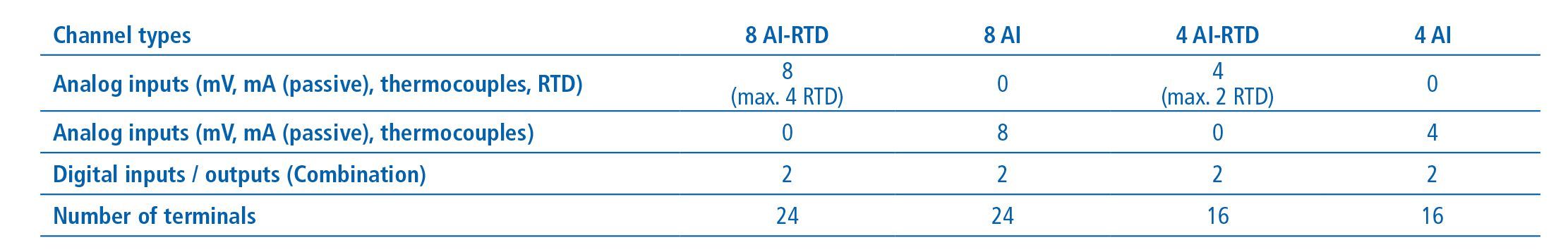

The Loggito USB Data Logger by Delphin can be used as a PC-connected data acquisition module or as an expansion module for the Loggito or Loggito WiFi systems. The Loggito USB is excellent as part of a distributed monitoring system, data acquisition with a low number of channels, and other low power applications in a wide variety of industries. The Loggito can be equipped with a variety of cards to provide 4 or 8 universal analog inputs for mV, mA, thermocouples, or RTD’s (-R model cards). Additional digital I/O cards are also available to provide up to 8 digital inputs/outputs.

When connected to a PC, the Loggito USB Logger can be used for data acquisition with the Delphin Profisignal software. Or, the Loggito USB can be used in conjunction with either the Loggito or Loggito WiFi as part of a stand-alone data acquisition or data logging system to provide additional analog inputs or digital I/O channels.

View more Delphin Technology products

Software

ProfiSignal Go enables users to portray measurement data online and offline and to carry out detailed analysis. The software can portray the Expert Logger‘s measurement data in trends. Users can choose between y(t) or y(x) diagrams as well as a range of other analysis diagrams. ProfiSignal Go is especially intuitive to make it highly user friendly.

Installation is very simple. It takes just a few mouse clicks to go from sensor connection to trend output.

Unlimited Trends

There are virtually no limits to trend portrayal for online and offline measurement data. Archived and online measurement data can be evaluated without having to interrupt ongoing measuring procedures. This is a unique function that is especially valued by customers.

In addition to y (t) diagrams are y (x) – and logic diagrams. The ProfiSignal Go Toolbox contains trend functions such as movable axes, zoom functions, cursors, markers and data export (e.g. as CSV or EMF files). Using the toolbox is self-explanatory. Configured trends can be saved and reused.

For visualization and automation functions, software upgrades to ProfiSignal Basic and ProfiSignal Klicks are possible at any time.

Alarm Functions

ProfiSignal Go also provides alarm management. A global alarm list provides a clear portrayal alarm notifications in tabular form. Alarm settings for the monitoring of over-runs, under-runs, process violations, status outcomes etc. are configured using the DataService/Configurator software. Measurement data can also be used to trigger specific actions, e.g. sending text messages or emails or switching digital outputs.

Interfaces and Drivers

Delphin products are equipped with drivers and interfaces to enable the import/export of data to external hardware and software. Laboratory equipment (e. g. scales, analysis/output devices) can be connected via USB and RS232/RS485 interfaces. A variety of protocols are available.

PROFIBUS and Modbus are used for data transfer between process control systems. The following interfaces are available for third-party software:

- LabVIEW™

- DASYLab™

- OPC-Server

- OPC Client

- Modbus TCP-driver

- OCX-driver

- GPS-converter