Month: January 2017

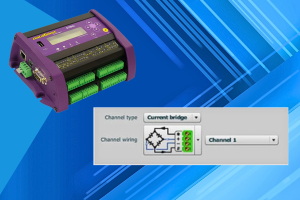

Strain Gauge Measurements With Current

Wheatstone bridge circuits are commonly used to measure the output of strain gauges and other sensors where small changes in resistance need to be detected.

How Do I Collect Data?

Using a Data Logger to Capture Data Saves Time and Cost Nowadays, every business and organization across every industry has heard about the benefits of collecting data. However, many people don’t know the best way to get started: for example, what device should you use, with what features and for what price? By using a … Continued

Requesting Support Files from Delphin

Walkthrough Covers How to Report Problems Delphin measurement systems are commonly used in data collection and test applications around the world. In our latest Tech Article, CAS DataLoggers and Delphin detail how you can generate a system report for your Delphin devices when requested by the manufacturer’s Support Team. This system report provides Delphin technicians … Continued