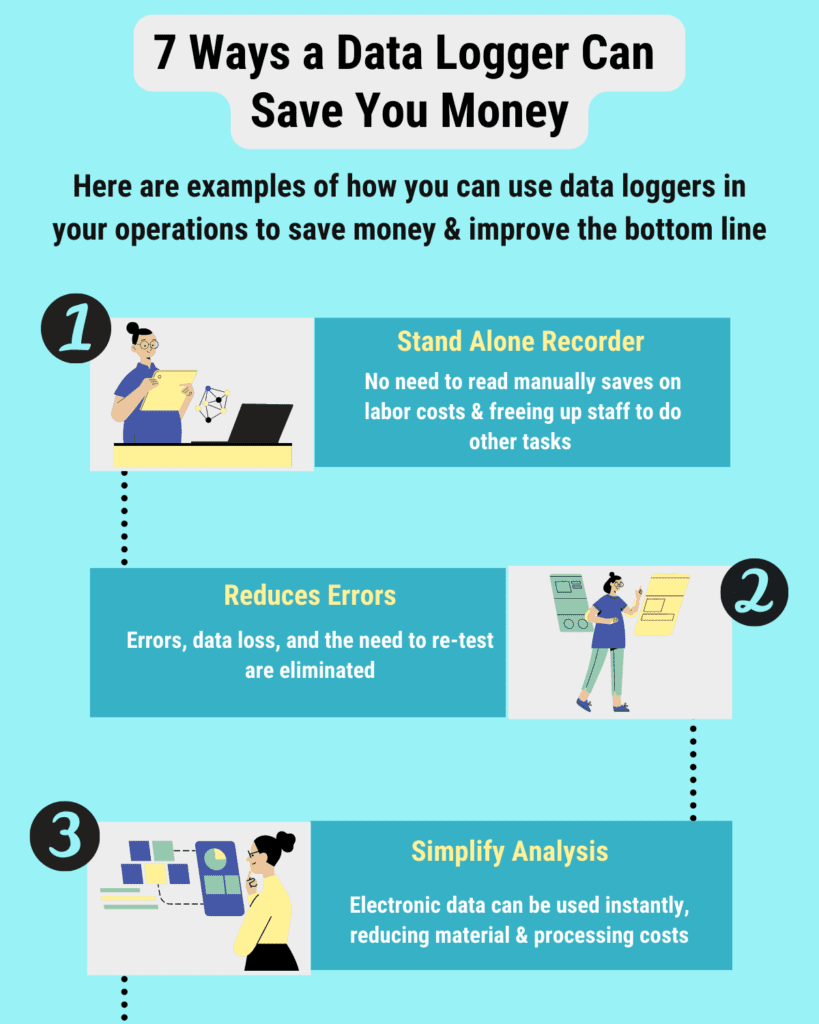

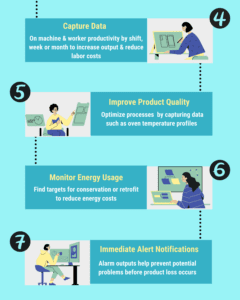

Every day we talk with dozens of customers to help them find the right data logger for their projects. One of the first questions we ask is “Why are you buying a data logger?” Our goal is to understand the problem they are trying to solve or the reason they are looking for a logger. Like many things, it often boils down to money: trying to reduce the cost of lost product or production or finding ways to improve quality and efficiency and reduce expenses. Based on the responses from customers in many kinds of industries with all different types of applications, we have compiled a list of 7 common ways that using a data logger can save you money.

Every day we talk with dozens of customers to help them find the right data logger for their projects. One of the first questions we ask is “Why are you buying a data logger?” Our goal is to understand the problem they are trying to solve or the reason they are looking for a logger. Like many things, it often boils down to money: trying to reduce the cost of lost product or production or finding ways to improve quality and efficiency and reduce expenses. Based on the responses from customers in many kinds of industries with all different types of applications, we have compiled a list of 7 common ways that using a data logger can save you money.

What Does a Data Logger Do?

First off, if you are not familiar with them, you might be asking yourself “What is a data logger?” We have an article devoted to this, but briefly, they are devices that record information by periodically taking measurements from external or internal sensors over an extended period of time. Data loggers are an ideal way to capture data by removing the need for personnel to spend time manually taking and recording measurements. In addition, many data loggers can provide alarm capabilities to notify staff if a measurement falls outside of the acceptable range.

Data loggers can record Temperature, Humidity, Current/Voltage, and many other types of data. They come in a wide range of styles and capabilities. There are small inexpensive single-channel models that can simply record just a few thousand points of one specific parameter, for example, the Switrace IPST8 single-use transit temperature logger. Other models like the 16-channel dataTaker DT85 can capture millions of points from multiple sensors, process the data as it’s collected, evaluate complex alarm logic, and automatically push the data to a server for further analysis and backup.

Examples

I thought it might be useful to provide some examples of how different data loggers are used in specific applications to get you thinking about how you might be able to employ data loggers in your operations to save money and improve the bottom line.

Remote Alarms Save Your Products

By continually monitoring temperature using a logger like the Accsense A2-05, which provides email and voice message alarms, you can be notified the instant that your environment goes outside safe temperatures. This is popular not only in medical and life science applications but also in food, beverage, and industrial monitoring applications. This feature alone can pay for the logger by helping to avoid a disastrous loss of product or a costly process delay!

Wireless Communication for Instant Access to Data

Wireless data logging systems with remote monitoring capability allow access to temperature data anytime, anywhere. The TR-71A is a temperature logger with two available sensor connections and can measure from -60 to 155 degrees Celcius. The wide range of optional sensors provides increased measurement flexibility. The software application used with the TR71A has a “Vaccine Mode”, which meets or exceeds CDC requirements for VFC and is useful for monitoring and recording vaccine temperatures. TR71A is useful not only in research labs and hospitals, but also in homes, offices, and other industries.

Prove Product Quality to Inspectors & Vendors

SwiTrace IPlug-IPST8 Data Loggers continually monitor product temperature whether in storage or transit, electronically storing the data for quality compliance purposes. These simple temperature monitoring solutions are easy to use, log automatically, and are designed to operate in any industrial environment. Built-in LEDs indicate if the product has been outside the acceptable temperature range allowing immediate acceptance or rejection of a shipment at the receiving location before it makes it into inventory. If you need a report, their built-in USB interface makes a connection to a PC for downloading the data a snap!

Proof of Regulatory Compliance

If you need compliance for FSMA, HACCP, FDA, or another industry regulation, data loggers like the Lascar EL-21CFR-2-LCD can easily capture and store critical measurements in an unalterable form as the basis for a documentation system proving regulatory compliance. As many of our customers have found, electronic record-keeping can dramatically reduce the cost of compliance reporting and virtually eliminate errors and missing data.

If you need compliance for FSMA, HACCP, FDA, or another industry regulation, data loggers like the Lascar EL-21CFR-2-LCD can easily capture and store critical measurements in an unalterable form as the basis for a documentation system proving regulatory compliance. As many of our customers have found, electronic record-keeping can dramatically reduce the cost of compliance reporting and virtually eliminate errors and missing data.

Not Sure Where to Start? Ask the Specialists!

At CAS DataLoggers, we work every day with callers to provide them with the ideal solution for their businesses. We want to help you select the most appropriate product for your application, no matter what field. Give us a call at 800-956-4437 or request more information to speak with one of our application specialists today and see how a data logger can save you money.

Leave a Reply

You must be logged in to post a comment.