ADwin Helps Ensure High Level of Quality Automotive Components

CAS DataLoggers provided the real-time data acquisition and control solution for an automotive manufacturer using test systems to determine the dynamic characteristics and parameters of their line of shock absorbers. On the factory’s production lines, test benches ensured a higher level of quality through individual component testing. All the test information and data needed to be transferred to a PLC control system via Ethernet or a Fieldbus interface so that it could then be stored as quality records in the production database. Management realized the need for a modular data acquisition and control system which could flexibly handle testing and could be easily configured to meet the demanding test specifications.

Installation

Installation

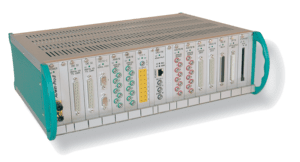

The manufacturer installed an ADwin-Pro-ll Data Acquisition and Control System in a control cabinet located in their testing area. The modular, expandable ADwin-Pro-ll system was suited for this application with its high channel capacity, flexible configurations, and field bus interfaces, including Profibus, CANbus, and serial interfaces enabling use with a PLC. The ADwin-Pro-ll formed an intelligent data acquisition solution performing an online evaluation of measurement data, immediately after each sample was taken. The system also handled complex triggering conditions, high analog sampling rates, and freely programmable mathematical operations and functions including RMS values, min/max, mean, derivative, digital filters, and frequency domain signal analysis.

Usage

The modular data acquisition system applied analog and digital stimuli to the shock absorber under test, using multiple channels of actuators and amplifiers. In addition to recording the stimulation, the response of the components was acquired by reading from the ADwin’s analog and digital input channels. The ADwin system evaluated the response in real-time to immediately calculate how well the shock absorber under test matched the manufacturer’s required specifications. The stimulation and acquisition could be performed over a very wide range of frequencies, from a few hundred hertz to several hundred kilohertz. By precisely timing stimulation, acquisition, and online evaluation, the ADwin system performed all tests and evaluated the data to accurately calculate the dynamic parameters of each shock absorber. The results were then sent to a PC operator interface connected via USB to display the test results.

The ADwin-Pro-ll real-time data acquisition system supported parallel, individually controlled, real-time processes, all while running independently of the PC’s operating system to provide deterministic operation with response times of 1 second or less. Tightly coupled analog and digital inputs along with counters provided extremely low latency operation. The system could also be configured for specific uses, utilizing a modular form factor with different I/O boards and expansion plug-in modules to allow up to 480 analog or digital inputs or any combination of these in a single chassis. The customer was also offered a variety of other I/O options including CANbus, SSI, Profibus/Fieldbus, RS-232/485, and signal conditioner modules.

Software

Additionally, the ADbasic development environment allowed users to program mathematical operations and functions which were executed immediately after each sampling step, even at sampling rates as high as 20 MHz. The ADwin software environment could be used under Windows (all versions) and Linux, or as a stand-alone data acquisition system. ADwin also offered drivers for most of the popular programming environments including Visual Basic, Visual C/C++, LabVIEW/LabWindows, MATLAB, and Simulink.

Benefits

The manufacturer benefitted in several key ways from installing the ADwin-Pro-ll data acquisition and control system in their shock absorber test program. The powerful ADwin system handled all the rigorous and fast-paced testing while its powerful communications options enabled data transfer to the PLC. The ADwin’s modular design made it simple to configure in line with all the test specifications, and the system could be easily expanded to accommodate future needs.

For more information on ADwin Data Acquisition Systems, real-time data acquisition or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.