dataTaker DT80 Accurately Measures Runtime & Energy Levels

Compressed air is a commonly used power source by manufacturers worldwide. As manufacturing capacity expands, compressor capacities also need to increase to meet the greater demand. Therefore it’s important to select a compressor with the correct capacity –if a compressor is too large for the job, it will only operate occasionally and draw a lot of power even while idling. A company specializing in compressor installation contacted CAS DataLoggers looking for a small but powerful data acquisition unit that field personnel could use for air compressor monitoring. They needed a system that would allow them to measure the runtime and current consumption on a wide range of their compressor models. This system also needed to be easy to use so that the company’s field engineer wouldn’t have to spend long hours learning how to program it.

Compressed air is a commonly used power source by manufacturers worldwide. As manufacturing capacity expands, compressor capacities also need to increase to meet the greater demand. Therefore it’s important to select a compressor with the correct capacity –if a compressor is too large for the job, it will only operate occasionally and draw a lot of power even while idling. A company specializing in compressor installation contacted CAS DataLoggers looking for a small but powerful data acquisition unit that field personnel could use for air compressor monitoring. They needed a system that would allow them to measure the runtime and current consumption on a wide range of their compressor models. This system also needed to be easy to use so that the company’s field engineer wouldn’t have to spend long hours learning how to program it.

Installation

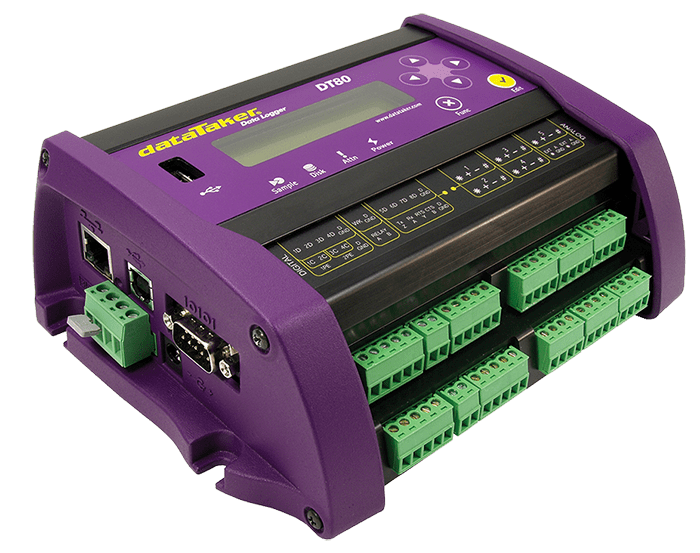

CAS DataLoggers supplied the business with a dataTaker DT80 Intelligent Universal Input Data Logger which their field engineer connected to a panel mount display. He then placed a current clamp around the compressor’s electric supply, allowing him to monitor the current used by the compressor in the loaded and idle states. In addition, using the universal analog inputs of the dataTaker, pressure transducers can be used to monitor output pressure from the compressor as well as motor temperatures. This additional data can be valuable in assessing the performance of the compressor.

Usage

The DT80 data logger features universal analog inputs, digital inputs/outputs, high-speed counter inputs, phase encoder inputs and serial sensor channels for connection to almost any sensor types. This application flexibility enables both current and runtime to be logged and archived on the logger’s 10 million data point memory for accurate air compressor monitoring.

The dataTaker data logger is now left onsite to automatically record the current levels and the ON time to OFF times. The logger’s USB memory stick and Ethernet ports, and RS232 with modem support let the user connect to the datalogger locally, remotely or via the Internet. The DT80 can also send the data via FTP for easy downloads or via e-mail attachment. Meanwhile remote access to logged data, configuration and diagnostics can be done via the DT80’s built-in web server. In this industrial environment, dataTaker’s rugged design and construction offer reliable low-power operation.

Free dEX software is included with all dataTaker loggers, which uses an integrated graphical interface. Using dEX, the user can configure the data logger, use mimics to view real-time data, generate charts and tables, and view historical data for analysis. This way, the engineer totalizes the runtime and current data collected over a week of recording, and at the end of the test period, the data is used in an energy survey to determine if the compressor is the correct size according to its demand.

Benefits

The installers benefited from having a single system able to monitor compressor runtime and energy levels, saving them the expense of buying multiple loggers each with their own software. Now the engineer can test all the air compressor units 1 or 2 at a time before installation. CAS DataLoggers also provided free tech support to help the field engineer program the dataTaker and use its totalizing capability to derive runtimes and current levels. Additionally, the logger can be connected to channel expansion modules to make it expandable to 100 inputs in case the scale of this testing application keeps increasing.

For further information on the dataTaker DT80 Intelligent Input Data Logger, air compressor monitoring, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.