Accsense Monitoring System Ensures Biobank is Compliant

CAS DataLoggers provided the automated temperature monitoring solution for a biorepository storing a wide range of life science materials including blood and tissue samples, common and experimental drugs, and many other high-value specimens and materials. Every material stored in the repository’s medical refrigerators, freezers and cryogenic tanks required continual temperature monitoring and historical data archiving to ensure the viability of the inventory as well as be compliant with the FDA’s Title 21 CFR Part 11 and other regulatory demands. To find a single solution addressing all these concerns, senior staff began searching for an automated temperature monitoring and alarm system capable of high-precision measurements and archiving, and advanced alarm features including calls over a landline or cell or to send text messages and email alerts. The system also needed to be both cost-effective and easy to use and maintain, with power over Ethernet technology to decrease the number of wires required to install the network.

Installation

Installation

The biobank installed 12 Accsense A2-05 Ethernet Wired Temperature Measurement Pods throughout their medical storage area, with temperature probes measuring in the medical refrigerators, freezers, and cryogenic tanks to provide continuous temperature monitoring. The Accsense automated temperature monitoring system supported power over Ethernet for quick and easy installation and setup, featuring centralized management with no software to install–workers just plugged the monitor into an active Ethernet port and the connection to the cloud was established.

Usage

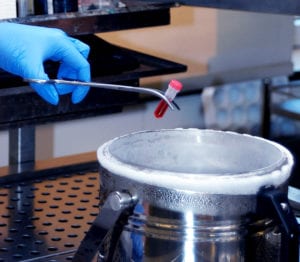

Specifically designed for measuring temperatures in medical refrigerators, freezers, incubators, and in cryogenic storage, the Accsense A2-05 LAN-wired data loggers each featured inputs for two external RTD temperature probes with a wide range of -100°C (-148°F) to +100°C (+212°F) for use in refrigerators and freezers, and an additional input for 1 thermocouple measuring from -200°C (-328°F) to +400°C (+400°F) for use in their cryogenic storage tanks, placing the probe in the unit’s vapor chamber. Each pod included a power adapter and Ethernet cables, supporting power over Ethernet for a lower cost and easier maintenance compared to traditional wiring. In case of a power failure or network connection loss, the Accsense system could keep running for 6 hours on its internal lithium battery, during which the data loggers would continue to buffer data. During outages, the pods could store up to 256 data points until connection was restored, ensuring that the data was continuous. Additionally, the wired pods could be utilized with other Accsense wired and wireless data loggers to further expand the system if desired.

As soon as they began recording temperature data from the biobank’s refrigerators, freezers and LN2 tanks, the A2-05 wired pods automatically sent all the information to the secure cloud servers where it was encrypted and stored. Personnel then used a web browser to access live and historic data and to configure alarms to activate whenever any unit’s temperature went out of specification. Operators utilized the Accsense system’s alarm capabilities by configuring telephone numbers to receive voice synthesized phone call alarms and text-based e-mails and test message alerts. Multiple wired monitors could also be viewed simultaneously from a single browser screen, and users could quickly login using any Web browser to retrieve reports and graphs or to modify the system’s configuration from anywhere an Internet connection was available.

Benefits

The biorepository benefitted immediately following installation of the Accsense wired automated temperature monitoring system in several key ways. The A2-05 Ethernet data loggers performed continual temperature monitoring for the medical refrigerators, freezers, and cryogenic tanks, and management relied on the system’s many alarm capabilities to deliver a phone call and other warnings of potentially disastrous events occurring such as freezer failures by showing that temperature had gone out of specification. Also, the Accsense wired system automatically sent its data to secure servers which provided the archiving and data storage functions needed to keep pace with Title 21 CFR Part 11 compliance. Additionally, staffers learned every aspect of the system’s user-friendly operation, with no need to rely on an IT department for training sessions.

For more information on the Accsense A2-05 Ethernet Wired Temperature Measurement System, other automated temperature monitoring systems or to find the ideal solution for your performance monitoring needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or request more information.