dataTaker DT80 Accommodates More Than 20 Measurements

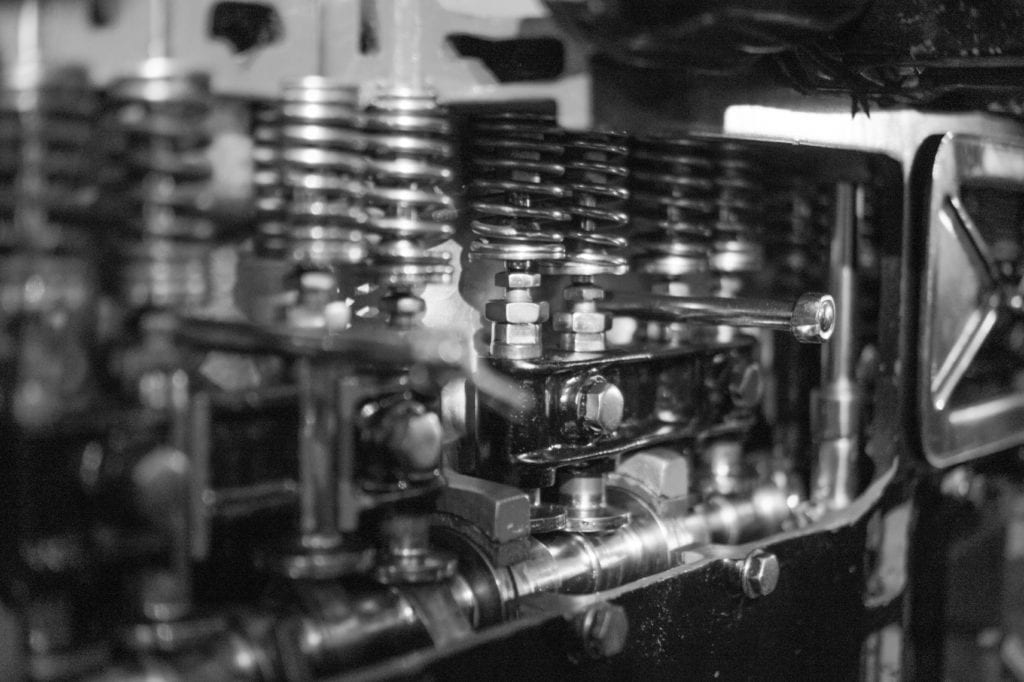

A large OEM manufacturer of automotive components needed to conduct a long-term test to evaluate the reliability of its latest device. This automotive component testing involved data collection from multiple vehicles at various locations across the US to study the effects of different use and environmental conditions on the components. The test was to run for 3 years to capture enough data for accurate statistical evaluation and lifetime predictions. It required more than 20 measurements including temperature, voltage and other operating parameters. Engineers began searching for an intelligent data logging solution with the versatility to accommodate all these different types of signal inputs. During the requirements definition, 3 other key concerns were identified: first, overall power consumption was very important–the logger only needed to collect data while the vehicle was running, but it had to be continuously powered so that it could quickly respond on startup. Therefore, the idle power consumption needed to be very low to eliminate the possibility of discharging the vehicle battery if it was parked for a long time period. Secondly, since the vehicles were dispersed throughout remote locations across the country, manual data retrieval was impractical, so the manufacturer wanted to implement a periodic automated data upload via a cellular connection. Finally, the data logging system needed to be as unobtrusive as possible, since these test vehicles were currently being driven by end users.

A large OEM manufacturer of automotive components needed to conduct a long-term test to evaluate the reliability of its latest device. This automotive component testing involved data collection from multiple vehicles at various locations across the US to study the effects of different use and environmental conditions on the components. The test was to run for 3 years to capture enough data for accurate statistical evaluation and lifetime predictions. It required more than 20 measurements including temperature, voltage and other operating parameters. Engineers began searching for an intelligent data logging solution with the versatility to accommodate all these different types of signal inputs. During the requirements definition, 3 other key concerns were identified: first, overall power consumption was very important–the logger only needed to collect data while the vehicle was running, but it had to be continuously powered so that it could quickly respond on startup. Therefore, the idle power consumption needed to be very low to eliminate the possibility of discharging the vehicle battery if it was parked for a long time period. Secondly, since the vehicles were dispersed throughout remote locations across the country, manual data retrieval was impractical, so the manufacturer wanted to implement a periodic automated data upload via a cellular connection. Finally, the data logging system needed to be as unobtrusive as possible, since these test vehicles were currently being driven by end users.

Installation

After extensive evaluation of different type of devices for vehicle data collection including data acquisition systems and data loggers, the customer selected the dataTaker DT80 data logger plus CEM20 expansion module for the test project. These intelligent low-power devices featured 5 flexible input channels that allow up to 10 isolated or 15 single ended analog inputs. A key feature of the logger is the multiple analog voltage measurement ranges from 30 mVDC to 30 VDC with 18 bit resolution allowing accurate measurement of very small voltage drops across contacts and cables up to full battery and charging voltage. Each DT80 datalogger featured a built-in display and removable screw terminals for secure connections. In addition to voltage, it can measure temperature, resistance, bridges, strain gauges and frequency. Any of the measured values could all be scaled to engineering units, logged with statistical reporting, or used in calculations. Since the number of inputs required was more than could be accommodated with the logger by itself, a CEM20 expansion module which provides 20 additional channels per unit was used. A total of 5 CEM20 modules can be added to the DT80 to allow up to 100 input channels.

After extensive evaluation of different type of devices for vehicle data collection including data acquisition systems and data loggers, the customer selected the dataTaker DT80 data logger plus CEM20 expansion module for the test project. These intelligent low-power devices featured 5 flexible input channels that allow up to 10 isolated or 15 single ended analog inputs. A key feature of the logger is the multiple analog voltage measurement ranges from 30 mVDC to 30 VDC with 18 bit resolution allowing accurate measurement of very small voltage drops across contacts and cables up to full battery and charging voltage. Each DT80 datalogger featured a built-in display and removable screw terminals for secure connections. In addition to voltage, it can measure temperature, resistance, bridges, strain gauges and frequency. Any of the measured values could all be scaled to engineering units, logged with statistical reporting, or used in calculations. Since the number of inputs required was more than could be accommodated with the logger by itself, a CEM20 expansion module which provides 20 additional channels per unit was used. A total of 5 CEM20 modules can be added to the DT80 to allow up to 100 input channels.

Usage

To power, the data loggers, a connection from the battery was run to the main power input of the logger while a separate wire was run from the keyed ignition signal to one of the digital inputs and the wake input of the data logger. The wire from the ignition was only energized when the ignition was on. Then, utilizing the ability to have multiple schedules within the data loggers and the capability of starting and stopping schedules under program control, a simple schedule triggered by the key turning on or off was created, and in turn, this schedule controlled the main data collection schedules within the loggers. Using the various configurable power settings, the loggers were set to go to sleep whenever the ignition was off to reduce power consumption to a minimum but wake immediately when the key was turned on to start recording data.

To simplify data retrieval, the dataloggers were paired with an Airlink Raven XE CDMA cellular modems that could be connected directly to the Ethernet port of the data loggers. Power for the modem was sent through the programmable Relay channel of the DT80. A timed schedule was created to trigger the data upload at a specific time each day. Once activated, this schedule would close the relay to power up the modem, wait for the modem to register, then establish its connection to the cellular network, send the data via the DT80s’ built-in FTP server and then power down the modem when done, again to minimize power consumption. Since multiple data loggers were used in the project, the upload times were staggered so that the loggers wouldn’t try to send their data to the server at the same time. All of the data was easily segregated by assigning each data logger a specific directory on the destination computer. A key feature of the data upload was the ability of the logger to keep track of what had been sent using an internal pointer to any new data which hadn’t yet been successfully unloaded. This allowed the dataloggers to automatically handle situations where the modem wasn’t able to make a connection to the cell network because of poor coverage or when the upload couldn’t complete successfully for some reason. To handle a worst case situation, the DT80 has USB memory slot which allowed the users to manually retrieve data by copying to USB stick.

Benefits

The DT80 dataloggers’ small size was another important part of the project. The manufacturer was able to conveniently package the DT80, CEM20 and cell modem in a fiberglass NEMA-rated enclosure that was less than .75 ft3. This enclosure was easily mounted in each car’s trunk, creating minimal impact for the vehicle owner and reducing the possibility of tampering. A remote cellular antenna was mounted close by on the underside of the rear shelf below the back window for good signal reception.

The manufacturer realized several key benefits from installing the dataTaker DT80 in its extensive automotive component testing program. The DT80 intelligent datalogger had the flexibility to accurately measure all the physical and electrical values including temperature and low voltage required by the demanding tests. These devices also featured the low power consumption, simplified data retrieval (enabled with a connection to the modem), and the small size that were all essential for this application.

About 18 months into the test program, the reliability of the data loggers has been very good. Most of the loggers uploaded data every night, and although some may have missed a day or 2 because of poor cellular coverage in their location, they recovered and uploaded any missing data once they got back to a better location. The quality of the measured data met or exceeded all of the customer’s expectations. In fact, the one hardware failure that occurred was attributed to the data logger being submerged as a result of a collision!

For further information on the dataTaker DT80 Intelligent Universal Input Data Logger, automotive component testing, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.