Simplified Barcode and Product Performance DAQ

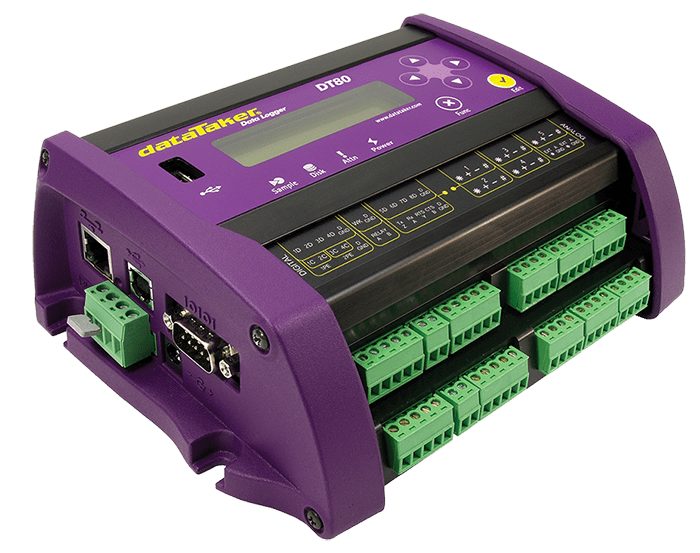

CAS DataLoggers receives requests from manufacturers who need a data logging system to collect data for final test and quality assurance purposes. In some applications, they would like to tag the measured data with information like a serial number by scanning bar codes on products coming off of manufacturing lines. For these projects, we have used the dataTaker data loggers including the DT80, DT85 and DT82I models depending on the number of inputs required. These intelligent universal input loggers can capture a scanned bar code via the serial sensor port plus additional values like voltage or current to track product quality, performance or compliance to specifications. In this brief tech article, we’ll go through the steps needed to set this up.

Scanner to Data Logger Connection

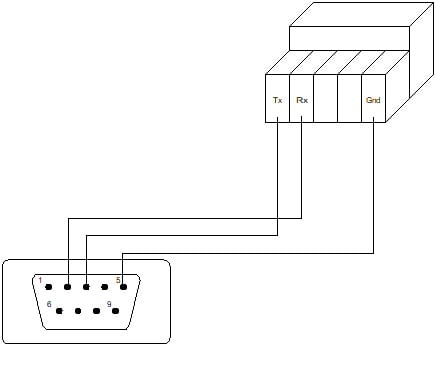

For this application, we connect a barcode scanner, for example, the like the Zebra DS22 to their dataTaker’s serial port. The DS22 is a handheld wireless scanner that comes with a docking/charging cradle with a standard serial connector. This connector is normally used with a PC serial port or serial to USB adapter. To connect it to the data logger we build an adapter cable to go from the DB-9 female connector of the scanner to the serial port of the logger.

Scanner and Serial Port Configuration

Scanner and Serial Port Configuration

The serial sensor port of the data logger is configured to match the serial port settings of the scanner, typically 9600 baud, 8 bits, no parity and 1 stop bit. Users then configure the barcode scanner so that whenever it scans a code, it appends a carriage return line feed to the serial string sent to the dataTaker. One very nice feature of the Zebra scanners is that they come with a set-up sheet that allows configuration of the scanner by simply scanning a barcode for on the setup instruction sheet.

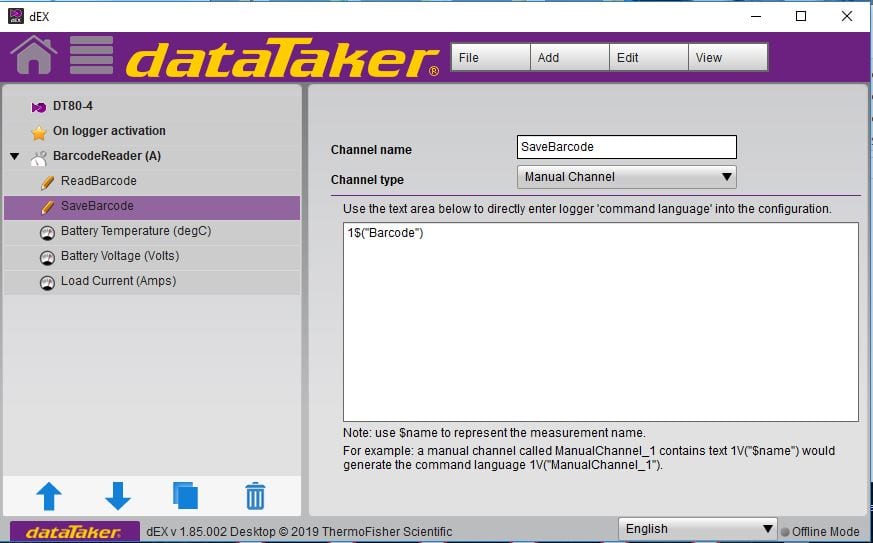

Data Logger Configuration

While it is possible to have the logger periodically check to see if there is new data from the serial port, adding the carriage return to the serial string simplifies the programming. A very nice feature of the data logger is that it can automatically trigger based on the receipt of either any serial character or a specific serial string. So, the logger waits until it sees the carriage return and triggers a schedule to run. This schedule reads the serial characters sent by the barcode reader and saves them in a variable, either as a text string or numeric value depending on the type of barcode. Within this schedule, the logger can also take measurements of any other required signals; this can be a product’s temperature, battery voltage, pressure from a sensor or just about any desired set of values. All of the data, the barcode and any other values are recorded in the non-volatile memory of the data logger along with a time stamp.

In addition to collecting the measurements for history tracking, it is also possible for the data logger to compare them to preset limits to indicate if the product meets the quality specifications or is defective. Whenever a value falls outside these limits, the data logger can generate an alarm, either locally via a digital output or remotely via an email or text message. The digital output can also be connected to an alarm light, siren, or other external contact warning device. The alarm information is also stored in a separate data store so it’s possible for users to pull the data at the end of the shift, day or batch to get a list of all failed products by their barcodes.

Benefits of dataTaker Loggers

The dataTaker loggers save time and improve the quality of reporting data. First, they remove the need to purchase additional devices; both captures of the barcode information and measurement of product performance can be done with a single device. There is no need to have one device to read the part serial number information and a second device to measure electrical data and then try to paste it together. Data quality is improved by automatically collecting everything at once, there is no worry about making sure that the measured data is for the correct part or problems with manually recorded data.

The free programming software included with every dataTaker logger makes set-up a snap. Also, recorded data can be viewed in mimics, trend charts, or tables, and users can also download historical data for analysis. These intelligent input data loggers allow connection to a wide range of sensors and data measurement sources to measure almost any signal including temperature, humidity, voltage/current, 4-20 mA loops, resistance, and many others. They also offer extensive communications capabilities including Ethernet, USB, Serial and cellular models.

These advanced features make dataTaker data loggers an ideal solution for real-time data acquisition, remote monitoring, and control needs. World-renowned for their robust construction, our dataTakers are built to last even in the face of extreme natural and industrial environments and years of nonstop use.

For further information on dataTaker Data Loggers, barcode scanners or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.