Measurement & Control Solution for a Manufacturer

CAS DataLoggers and Delphin Technology provided the measurement system for a large manufacturer of valve systems used in many different industries. The company produces ball, needle, choke, control, gate, and other types of valve systems with many different diameters. One of its customers was a refinery using a custom 3-way switching valve in order to direct the flow of tar sand into different coking towers. However, the operation of the valve was not always reliable, and when it failed it resulted in costly shutdowns in the refining process. Therefore, a data acquisition system capable of connecting to several different kinds of sensors was needed for coker valve monitoring, and provide real-time data that could be used to determine if the valve was working properly. The device needed to be simple to configure and operate, including data analysis software, and also offer a modular design to accommodate possible expansion to add more input and output channels in the future.

Installation

Installation

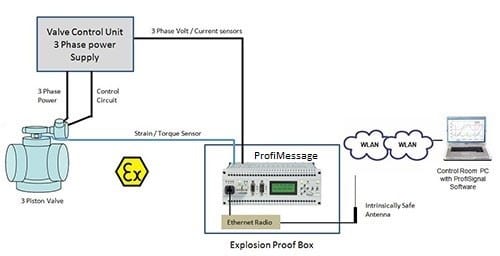

The manufacturer installed a Delphin Expert Transient Data Acquisition & Control System close to the valve control unit in order to capture all data describing the valve’s operation and movement. The Expert Transient features 8 fast (up to 50 kHz) synchronous sampled analog inputs. The DAQ system was placed into an explosion-proof enclosure in the hazardous zone; its compact design allowed it to fit neatly into the small space inside the enclosure. Real-time communication to the control room was enabled by a wireless spread spectrum radio link connected to the Ethernet port of the system.

The ProfiMessage system measured the 3-phase motor current and voltage plus the force required to open or close the values. The installed sensors included:

- One strain gauge with signal conditioner for torque measurement

- One motor voltage transducer

- Three motor current transducers

- Two control circuit voltage transducers

Figure 1. Installation of the ProfiMessage

The inputs were configured for a 1 kHz sample rate each, and the measurements from all 8 channels were recorded into onboard memory. Data transfer was accomplished through the wireless radio link. Using the internal software channels of the Expert Transient, logic was created in such a way that storage of the data was triggered at a specific threshold level of motor current consumption, ensuring that only relevant data during the valve movement was recorded. These logic functions also allowed the user to configure the Expert Transient with event-based functions to alarm on specific conditions.

Usage for Coker Valve Monitoring

Usage for Coker Valve Monitoring

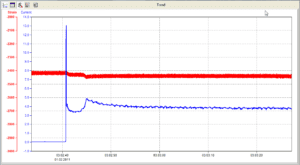

The Delphin Expert Transient provided a modular and scalable system capable of highly accurate measurements with up to 24-bit resolution. The system measured all the data from each valve cycle, only recording data when while the valve was in operation. At the end of the valve movement, an event triggered automatically to upload data from the system to a PC in the central control room via the wireless Ethernet link for analysis. Data analysis and processing were facilitated using Delphin’s powerful ProfiSignal Basic Software. The operators were interested in the relationship between motor current consumption and the torque profile during the valve movement, which gave a clear indication of when the valve performance was degrading. Knowing when the valve was degrading allowed them to schedule maintenance action before failures could occur.

Benefits

The manufacturer benefited in several key ways after installing the Delphin Expert Transient system in its customer’s refinery. The system was highly accurate and reliable, with the programmability to allow it to record only relevant data. The high-speed, synchronous measurements made it easy to capture the specific data of coker valve monitoring, which would indicate a pending failure. The compact size of the Expert Transient allowed it to be installed in an explosion-proof enclosure very close to the valve. Automatic data transfers were uncomplicated to set up and streamlined the data acquisition process. The Profisignal software allowed them to easily set up the calculations and charts necessary for efficient data analysis and problem identification. The net result was that the customer was easily able to continually monitor the valve to check its performance and schedule maintenance before its operation could fail, preventing unscheduled interruptions in processing.

For more information on Delphin data acquisition system, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or request more information.