Using the Bestselling dataTaker DT80 Intelligent Data Logger

CAS DataLoggers provided a local construction company with the data logging solution for one of their larger contracts. The customer needed to measure and monitor the curing progress of freshly-poured concrete to determine when the new structure could be loaded without causing damage to its foundations. With industry-accepted concrete curing temperature methods, a newly-poured concrete structure does not reach full strength for a considerable period of time, but it was critical to determine exactly what that duration was to speed construction along and complete the project on schedule. This complex procedure required a data logging solution capable of not only temperature measurement but also being able to sense the localized effects of air temperature and of reinforcing rods that acted as heat sink–information that could not be determined by traditional sampling procedures. This device would also have to be protected from the harsh late autumn weather and feature a wide range of communications capabilities to send the data over the Internet as well as locally.

Installation

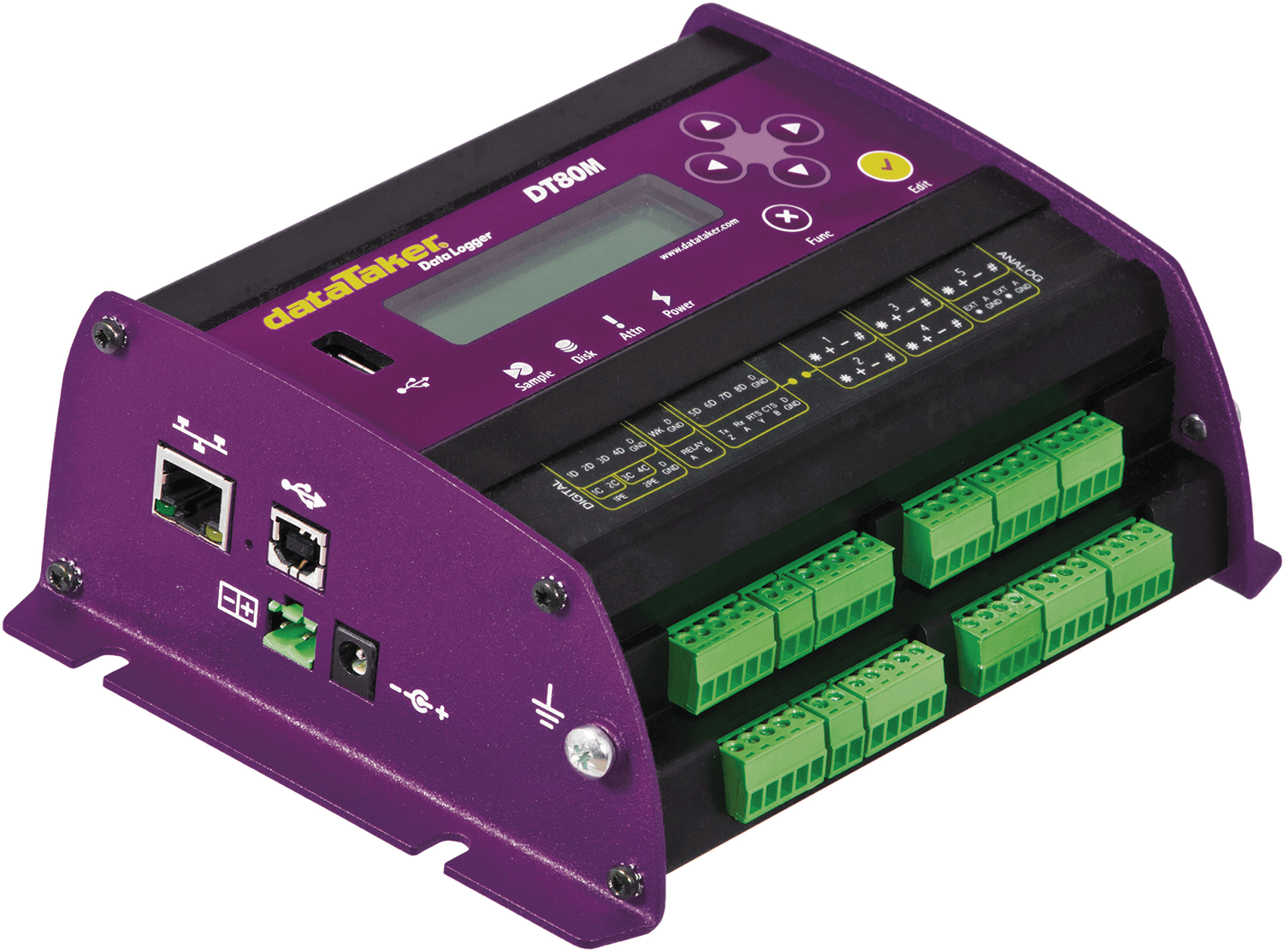

The customer installed a dataTaker DT80 Intelligent Universal Input Data Logger adjacent to the freshly-poured structure. The data logger was housed in a portable rugged weatherproof enclosure for protection onsite. Subsequently, the dataTaker device was used to measure the exothermic heat generated by the concrete as it was curing, measuring temperature via thermocouple wires connected to the logger and cast directly into the concrete. The company’s custom software was specifically tailored to suit all data loggers in the dataTaker range and used this temperature data to calculate and display the progressive development of the concrete’s strength, predicting its 28-day strength after a full day of curing.

Usage

The dataTaker DT80 low-power data logger featured an 18-bit resolution and a ±30 V input measurement range with a Dual Channel concept allowing up to 10 isolated or 15 commonly referenced analog inputs to be used in any combination. Equipped with 5 to 15 universal analog sensor inputs and 12 digital channels, the stand-alone logger performed data acquisition in real time, featuring a built-in display and removable screw terminals for secure connections. High-speed counter inputs, phase encoder inputs, and a programmable serial sensor channel allowed the DT80 to easily connect to most sensors and data measurement sources so that temperature, voltage, current, 4-20mA loops, resistance, strain gauges, frequency, digital, serial, and calculated measurements could all be scaled, logged and returned in engineering units or with statistical reporting. Engineers could also group sampling, logging, alarm, and control tasks within schedules to suit their requirements.

Data management was simple, with the datalogger storing up to 10 million data points in user-defined memory so that engineers could log as much or as little as needed with independent control of schedule size and mode, and also overwrite or stop logging once the allocated memory was full. Data transfer via the logger’s extensive communications array included Ethernet, RS-232 communication with PC, Modbus sensor support, and a USB memory slot. With this versatile device, operators could archive data on alarm event, copy to USB memory, or transfer it via FTP.

In addition, dataTaker’s dEX user-friendly graphical interface was included free of charge with the data logger. This intuitive, browser-style software came pre-installed and enabled quick setup and configuration of the logger, suitable for both novice and advanced users. The software ran and was configured directly from a web browser, so it could be accessed either locally or remotely over the Internet. Operators could use any of the logger’s built-in communications ports to view dEX, including Ethernet and USB.

Benefits

The construction company benefited in several key ways after installing the dataTaker DT80 datalogger in their concrete curing temperature monitoring project. This one device measured not only the exothermic heat recordings from the thermocouple sensors but also the air temperature and the heat sink effects of the reinforcing rods. Additionally, the weatherproof enclosure enabled the datalogger to keep logging in spite of inclement weather and also protected it from dust and other onsite hazards. Operators found it easy to work with the included dEX software for hassle-free configuration of the logger, and the DT80’s many communications options offered data transfer locally via USB or online through FTP. Loading commenced on the structure with no time wasted, ensuring the job stayed on schedule.

For more information on the dataTaker DT80 Intelligent Data Logger, concrete curing temperature or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.