Cost-Effective Wireless Temperature Monitoring System from TandD

CAS DataLoggers provided the automated food safety monitoring solution for Longhini Sausage Co. Inc, a family-owned business serving the Southern Connecticut area for almost sixty years. The business’s products are found in many of the area’s restaurants, delis, and supermarkets.

CAS DataLoggers provided the automated food safety monitoring solution for Longhini Sausage Co. Inc, a family-owned business serving the Southern Connecticut area for almost sixty years. The business’s products are found in many of the area’s restaurants, delis, and supermarkets.

Uncooked sausage is a perishable, very temperature-sensitive product. During storage, if the sausage temperature rises above 35°F (1.6°C), owner Rich Longhini says he has a problem. He explains, “We load our trucks the afternoon before shipping the next day and on a given night I could have $15,000 to $20,000 worth of product stored in my trucks. Last year, one of my refrigerated trucks went out of the temperature range overnight and we did not find out until the next morning. This caused us to throw away over $3,000 of product. After that, I wanted to monitor the temperature in the refrigerated compartments so I would be notified with an alarm message if the temperature rises in the middle of the night.”

Longhini began searching for an automated alarm system to monitor his refrigerated trucks. His primary requirement was for a wireless temperature monitoring system capable of providing remote alarm notification. The first systems he found, including systems expressly designed for refrigerated trucks, provided many capabilities like alarm notification but came at a high cost. However, he didn’t want or need the extra functionality, just a reliable way to protect his product.

Effective Cold Chain Monitoring

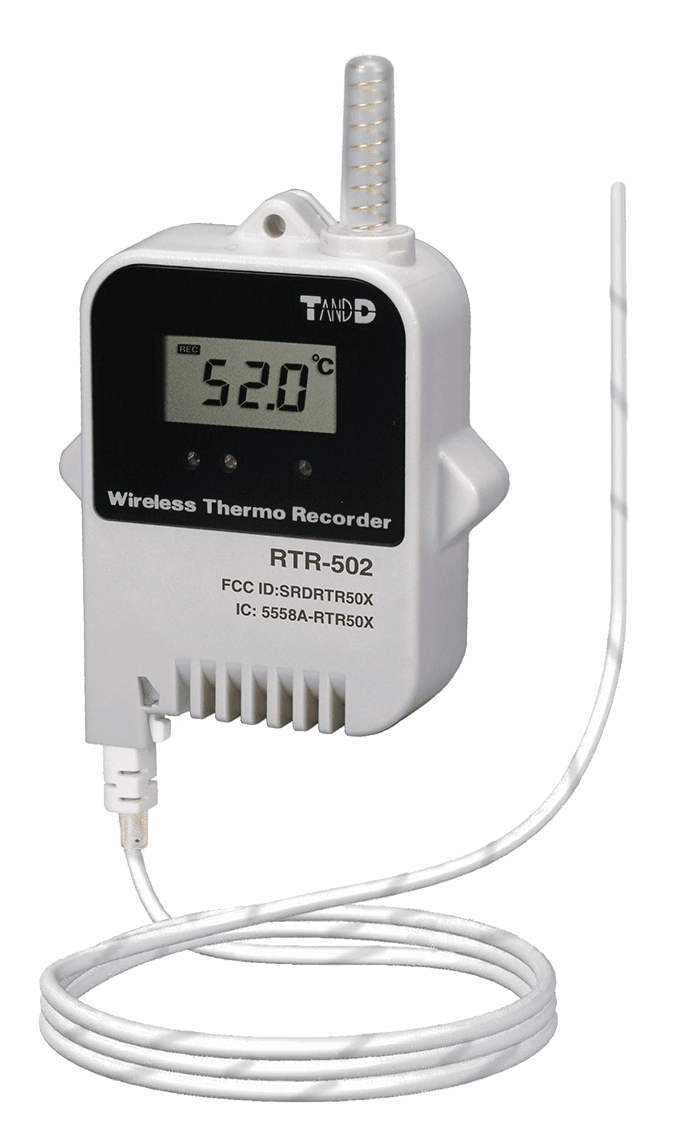

After searching online, Rich Longhini contacted CAS DataLoggers. He described his application and requirements from which several potential solutions were identified. Rich considered many options but eventually decided on T&D’s RTR-500 Wireless Data Logging System. CAS provided his business with three RTR-502 Wireless Temperature Data Loggers and an RTR-500NW Ethernet Base Station to monitor the temperature in the refrigerated compartment of his trucks.

In operation, the three delivery trucks are parked in the garage as they await the morning deliveries, each one with a T&D data logger mounted on the outside in an exterior weatherproof box. The RTR-502 loggers are compact, smaller than a deck of cards, for easy placement. Longhini installed the system himself, drilling a small hole through the side of each truck and routing the loggers’ temperature probes inside the roof alongside the refrigeration unit’s own probe to the warmest part of the refrigerated compartment.

In operation, the three delivery trucks are parked in the garage as they await the morning deliveries, each one with a T&D data logger mounted on the outside in an exterior weatherproof box. The RTR-502 loggers are compact, smaller than a deck of cards, for easy placement. Longhini installed the system himself, drilling a small hole through the side of each truck and routing the loggers’ temperature probes inside the roof alongside the refrigeration unit’s own probe to the warmest part of the refrigerated compartment.

The data logger’s sensors have a measuring range of -76°F to 311°F (-60°C to 155°C) to monitor product or environmental temperature in real-time. Users can choose to record in Celsius or Fahrenheit. Each data logger has a 16,000 point internal memory along with a standard battery life of about 10 months. However, Longhini opted for units with an optional large-capacity lithium battery pack which provides up to 4 years of operation extending the reliability of the alarm monitoring solution on the refrigerated trucks.

Going Wireless

Now, the wireless T&D system now continually monitors the temperature in the refrigerated compartment of the fully-loaded trucks while they’re parked in the garage each night. The loggers automatically take a temperature sample every ten minutes without any human intervention.

Data is then relayed through the RTR-500NW network base station, which is located on the garage wall 50 ft. away from the trucks well within the expected communication range of 500 ft. The RTR-500NW automates monitoring, alarming, and data retrieval from the data loggers. The base station has a standard 10/100BaseT Ethernet interface to connect to the network and automatically send the data directly to Rich Longhini’s PC or to the T&D WebStorage Service. Also, if needed, changes to settings can be made over the network and sent to the base unit remotely.

Alarm & Remote Data Transmission

Longhini occasionally views the data uploaded to the WebStorage Service from his home PC, but as long as the system is on, his product is continually monitored. His preset temperature ranges for this application are 26°F at the low end with a high limit of 35°F, and he adjusted the temperature parameters in the trucks to compensate for defrost cycles. The system’s alarm sampling checks are performed at the same rate as temperature sampling.

Whenever a reading shows that the refrigerated compartment has gone out of the desired temperature storage range, the system sends an email alarm via the network directly to Longhini’s email address. He comments on the critical importance of this feature, “99% of the time when you get a temperature alarm for food in storage, it’s telling you that you have a real problem and you need to hurry. There aren’t many false alarms, so this usually means the truck refrigeration unit just failed and your safety window is shrinking. You just can’t afford to miss an alarm in this business.”

Now when a temperature excursion occurs overnight, Rich will immediately get an alarm notification sent to his mobile device. He gives an example of how an alarm event would arise: “It’d be on a weeknight—I’d first notice it as an email from my phone. From home I’d log in to the T&D Current Readings Monitor, look at the alarms, and then decide what action to take. That could mean emptying the affected truck or moving product from one unit to another…whatever it takes to get it back in temperature spec ASAP.”

Proving Product Quality to Customers

Another business priority for Longhini is archiving the temperature data as proof of product quality. In addition to performing configuration and setup, the included T&D software enables him to create charts and graphs showing the temperature history: “It’s a convenient backup that I can use as proof to my customers that my shipments stayed in temperature for the entire length of storage.”

.

Benefits

The T&D RTR-500 Wireless Data Logging System has completely automated the Longhini Sausage cold chain monitoring setup. After the quick installation and setup, Rich is now assured that his trucks are ready to deliver a quality product the next morning. Before installing the system Rich would worry, lose sleep, and occasionally drive back out to make sure everything was okay.

It is no surprise when asked to name the biggest benefit of his new system, Rich replied, “Just knowing that my product is safe unless the system tells me different provides peace of mind. Getting an alarm directly on my phone is also nice. I would recommend T&D–it works, it’s cost-effective and you guys at CAS DataLoggers will take good care of me with technical support.”

For further information on TandD Wireless Data Loggers, food safety monitoring or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.