Thermocouple Data Loggers Save Time & Improve Safety

Concrete maturity is a measure of how much a batch of freshly poured concrete has cured and is a quick indicator of the in-place strength at that time relative to when it is fully cured. Traditional measurements of concrete strength rely on lab tests of field cured sample cylinders of concrete made in parallel with the main pour or pullout or penetration tests made on site. The concrete maturity method calculates an index based on time vs. temperature data and then using the strength-maturity relationship one can determine a good estimate of the strength at that point in time. This technique is attractive because it can be done quickly on-site with a temperature data logger and thermocouple sensors embedded in the pour. Using the concrete maturity index is favorable because it can save time and improve safety by allowing form removal, post-tensioning, joint sawing, or putting structures in service knowing that required strength has been obtained.

What is the Concrete Maturity Index?

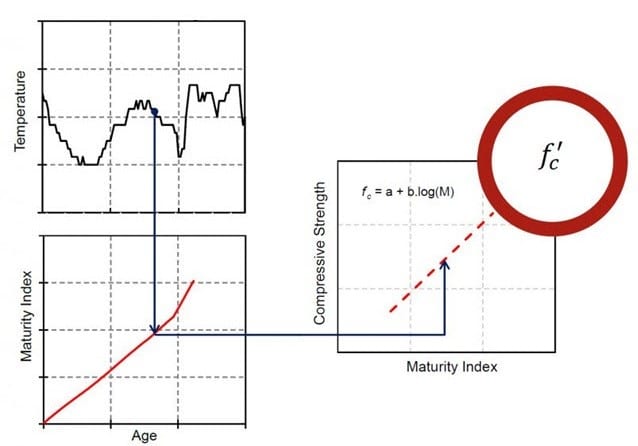

The maturity method is based on the idea that the strength of concrete is based on the hydration of cement in the mix. This hydration is an exothermic reaction that gives off heat. By recording the temperature profile at regular time intervals during the curing process, you can estimate the maturity and from this, the estimated strength of the concrete on-site and in real-time without having to send samples to a lab for more traditional tests. ASTM International had created a standard procedure, ASTM standard C 1074, for estimating concrete strength using the maturing method. This method requires an initial calibration process that uses the evaluation of the concrete maturity index in parallel with a more traditional compressive strength test to develop the concrete maturity index vs. strength curve. Once this curve is established it is assumed to be valid for any pours that use the same mix recipe.

The maturity index is calculated from the raw time-temperature data using one of 2 expressions:

1. The temperature-time factor:

M(t)= ∑(Ta-To)∆t

Where: M(t)= Maturity temperature-time factor

M(t)= Maturity temperature-time factor

Ta = Average temperature during a time interval

To = Datum temperature below which no hydration occurs

Δt = time interval between measurements

2. Equivalent age using an Arrhenius function:

t_e= ∑e^(-Q(1/Ta- 1/Ts) ∆t

te = Equivalent age

Q = Activation energy divided by gas constant K

Ta = Average temperature during the time interval

Ts = Datum temperature below which no hydration occurs

Δt = time interval between measurements

Of these 2 methods, the second is more accurate, but the first is considered good enough for most applications.

How to Measure the Concrete Maturity Index

The use of the maturity method in real applications requires 3 pieces. First, temperature sensors need to be embedded in the pour. The simplest way to accomplish this is to obtain a spool of thermocouple wire, commonly 20 to 24 gauge solid K or T type wire. The actual sensor is created by stripping a short length of wire, approximately 1/2”, and then twisting the two conductors together. The sensor is placed in a convenient location in the pour, either before or immediately afterward. It’s important that the sensor is in good physical contact with the concrete. The thermocouple wire is extended out to a spot where the data logger can be placed out of harm’s way.

For the data logger, a simple battery-powered stand-alone unit like the Grant Squirrel OQ610 or VersaLog VL-TC allows temperature data for multiple locations to record. There are also wireless units like the VersaLog VL-WF-TC which uses WiFi, the TandD TR-45 Bluetooth logger for use with mobile devices, or the TandD RTR-505-TC which allows streaming the data back to a computer in real-time.

For the data logger, a simple battery-powered stand-alone unit like the Grant Squirrel OQ610 or VersaLog VL-TC allows temperature data for multiple locations to record. There are also wireless units like the VersaLog VL-WF-TC which uses WiFi, the TandD TR-45 Bluetooth logger for use with mobile devices, or the TandD RTR-505-TC which allows streaming the data back to a computer in real-time.

The last piece is the software for analysis and calculation of the concrete Maturity time-temperature factor or equivalent age. The equations above can be quickly created in Microsoft Excel. All of the previously mentioned data loggers allow recorded data to be exported as a CSV text file that can be easily imported into Excel. An example template for the Grant OQ610 can be downloaded here.

Conclusion

The Maturity Index provides a convenient way to estimate the in-place strength of concrete during curing. It is based on the principle that the strength is can be determined based on the temperature-time history during the curing process. Using a thermocouple data logger with simple thermocouple temperature sensors embedded in the concrete allows the data to be recorded. This data can then be quickly analyzed using a tool like Excel to calculate the maturity index.

For more information on concrete temperature monitoring, or to find the ideal solution for your specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or request more information.