Delphin Expert Logger Data Acquisition and Control System

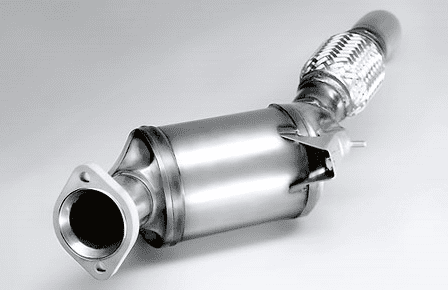

CAS DataLogger’s partner Delphin Technology provided a vehicle data acquisition solution for Twin-Tec. This company is a German developer and manufacturer of environmentally friendly products and technologies for reducing exhaust emissions, including a wide range of diesel particulate filters and catalytic converters for automotive applications. Twin-Tec was involved in producing products for retrofitting existing vehicles as well as corresponding replacement products. In Germany, the government encouraged all owners through financial incentives to retrofit their filters since many old vehicles had no diesel particulate filtration. Many German automobile owners became interested in adding a particulate filter to their exhaust system to protect the environment and benefit from the reduced vehicle emission taxes.

CAS DataLogger’s partner Delphin Technology provided a vehicle data acquisition solution for Twin-Tec. This company is a German developer and manufacturer of environmentally friendly products and technologies for reducing exhaust emissions, including a wide range of diesel particulate filters and catalytic converters for automotive applications. Twin-Tec was involved in producing products for retrofitting existing vehicles as well as corresponding replacement products. In Germany, the government encouraged all owners through financial incentives to retrofit their filters since many old vehicles had no diesel particulate filtration. Many German automobile owners became interested in adding a particulate filter to their exhaust system to protect the environment and benefit from the reduced vehicle emission taxes.

Twin-Tec was therefore developing a line of retrofit filters for many different automobile models. Each filter required testing on the road under typical driving conditions to determine filter efficiency—however, virtually every new filter also required a new design due to the wide variety of exhaust systems and their operating conditions. During test drives, the filter temperature, exhaust gas back pressure, engine speed, idle times, vehicle position, and speed all needed to be measured accurately and reliably to ensure that the filter met all required standards. To record all the test data, Twin-Tec needed a flexible data acquisition system capable of collecting accurate data from a wide range of sensors required in the tests.

Installation

Installation

Twin-Tec installed a Delphin Expert Logger 200 together with a Garmin GPS-18 sensor to record measurement data from the filters in tandem with vehicle position information. The whole system was installed in a small weatherproof enclosure and its sensors were interfaced to the enclosure through special connectors. During the test drive, data was recorded in the Expert Logger’s internal memory. Engine RPM was recorded through a separate magnetic pickup which provided a pulse output. The pulses were fed into a counter input of the Expert Logger, scaled, and converted to RPM. Exhaust gas back pressure was measured using a low-range pressure transducer with a 0-5 VDC output mounted on a standoff tube to protect it from direct exposure to the high-temperature exhaust gas stream. Exhaust gas temperature was measured using a thermocouple probe from Exhaust Gas Technology designed specifically for this application.

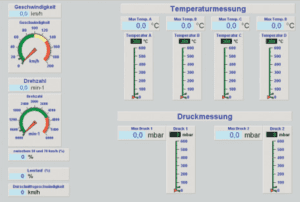

To view live data during development and testing, a dashboard screen was created in ProfiSignal Basic software. The Expert Logger 200 featured 21 analog inputs and 8 digital inputs/outputs as well as Ethernet and CANbus interfaces. The analog inputs could be attached to thermocouples, voltage, or 4-20 mA signals, enabling any physical measurement to be recorded. The measurement data was saved as scaled engineering units and linearized to the device. The high measurement accuracy, up to a 24-bit resolution, enabled precision measurements without the need for separate signal conditioning. The Expert Logger could run off 12 VDC, so it could be powered directly off the vehicle.

Usage

The Expert Logger can process each input signal quickly and reliably from all of the different analog sensors for temperature and pressure plus the digital output of the RPM sensor. With 16 GB of internal memory allowing stand-alone operation, it could easily record all of the data from multiple test runs with different driving conditions. To record the vehicle’s speed and direction, a driver for a GPS sensor was developed. This GPS-18 was interfaced with the Expert Logger through one of its built-in serial ports. The driver decoded all of the key GPS information like speed, position, and direction and save it in parallel with the other data in internal memory.

After the test drive was finished, all the data could be downloaded and analyzed with the Delphin ProfiSignal software. This user-friendly software was used for configuration of the input channels, processing, and analysis of the data and export to .csv form for reporting. It was also possible to convert the GPS data into a KLM file which could be loaded by Google Earth to plot the data against map position.

Benefits

Twin-Tec benefitted immediately from installing the Delphin Expert Logger 200 system for in-vehicle data acquisition for its diesel particulate filter testing program. Filter temperature, pressure, engine speed, idle times, vehicle position, and speed were all measured during the test drives using one device. The universal analog inputs made it easy to connect all the temperature and pressure sensors, and engineers found it easy to configure the ProfiSignal software to show live reading during the test drives. The vehicle data acquisition system’s 16 GB internal memory provided storage capacity for hundreds of kilometers of test drives, and the interface of the GPS sensor also gave Twin-Tec valuable additional information about vehicle speed in combination with engine RPM and particle emission. Additionally, the small and compact size of the Expert Logger (200x73x118 mm) made it an ideal fit for installation in the small enclosure.

For more information on the Delphin Expert Logger, vehicle data acquisition systems, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or request more information.