Fresh Cut Flower Farm Uses Automated Greenhouse Monitoring

CAS DataLoggers provided the greenhouse temperature monitoring solution for a large greenhouse currently cultivating several species of popular flowers, an extremely temperature and humidity sensitive process. The temperature and humidity requirements varied from flower to flower, with ideal temperature limits usually being between 57°F and 82°F (14°C to 28°C) with a humidity of 70%-100%.

CAS DataLoggers provided the greenhouse temperature monitoring solution for a large greenhouse currently cultivating several species of popular flowers, an extremely temperature and humidity sensitive process. The temperature and humidity requirements varied from flower to flower, with ideal temperature limits usually being between 57°F and 82°F (14°C to 28°C) with a humidity of 70%-100%.

Temperature and humidity were both measured at the head of the plants for the most meaningful results and were the largest factors in making up the greenhouse’s delicate microclimate. To obtain maximum growth efficiency, it was essential that the correct temperature and humidity conditions be maintained throughout the growth of the crops. Temperature and humidity were also the primary indicators used to collect disease prediction data –the earliest warning of disease and mold before they could overwhelm whole species.

Early on, the growers had been relying on inexpensive glass and electric thermometers for temperature measurement, but these proved to be too time-intensive and inaccurate. Staff needed to quickly compare current measurements with previously recorded data to get an idea of how to conduct temperature profiling for their disease prevention processes. Soon the greenhouse was equipped with a climate control system to automatically control temperature and humidity, but staff realized that the system’s drawback was that the climate control was limited to fixed places. What the owner and growers needed was a temperature and humidity monitoring solution powerful yet affordable enough for all greenhouse operations; a flexible solution to mapping humidity distribution as well as hot and cold spots and the effectiveness of ventilation, heating, and irrigation. Additionally, all current conditions of the measurement cycle would have to be available immediately for quick correction.

Installation

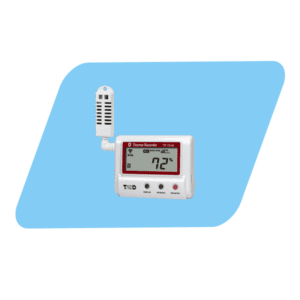

The greenhouse installed four T&D TR-72wb temperature and humidity data loggers in major areas not covered by the existing climate control system. Each T&D data logger monitored temperatures across a -0°F to 131°F (0oC to +55oC) range with an internal temperature sensor as well as recorded humidity using the external sensor’s range of 0 to 95% RH. The T&D logger’s 0.5ºC resolution provided highly accurate readings which were clearly displayed on each logger’s large LCD display, featuring multi-function viewing to show climate data in real-time. Each logger’s memory stored up to 16,000 samples (at 8,000 per sensor) with a user-set sampling frequency from every second to every hour. Customized alarm settings notified growers whenever temperatures suddenly went out of specification, and together with T&D’s no cost, WebStorage Service cloud hosting, remote access to the data was simple and easy to use.

Usage

Personnel were able to quickly install the TR-72wb’s and connect them to the WiFi in the greenhouse. The dataloggers monitored the microclimate in tandem with the climate control system, covering the ‘blind spots’ in its fixed sensors. Functioning like portable weather stations for monitoring the greenhouse in detail, the humidity loggers gave key information on the microclimate, such as temperature drops or changes in the diurnal range, by linking the temperature to the humidity info. This combination of historic and current data was invaluable when growers collected comprehensive meteorological information to reduce risk to the crop by taking measures to limit the negative effects of uncontrollable environmental conditions. This allowed them to achieve optimum plant growth while minimizing disease risk. As opposed to walking up to a thermometer to read the temperature and recording it manually, all this climate information was stored on the data logger and accessible via an Internet browser connection from anywhere. The logger also aided in disease prediction from gray mold, powdery mildew, and other diseases which depended on temperature and humidity conditions, so the growers knew when to spray and when to remove infected vines.

Personnel were able to quickly install the TR-72wb’s and connect them to the WiFi in the greenhouse. The dataloggers monitored the microclimate in tandem with the climate control system, covering the ‘blind spots’ in its fixed sensors. Functioning like portable weather stations for monitoring the greenhouse in detail, the humidity loggers gave key information on the microclimate, such as temperature drops or changes in the diurnal range, by linking the temperature to the humidity info. This combination of historic and current data was invaluable when growers collected comprehensive meteorological information to reduce risk to the crop by taking measures to limit the negative effects of uncontrollable environmental conditions. This allowed them to achieve optimum plant growth while minimizing disease risk. As opposed to walking up to a thermometer to read the temperature and recording it manually, all this climate information was stored on the data logger and accessible via an Internet browser connection from anywhere. The logger also aided in disease prediction from gray mold, powdery mildew, and other diseases which depended on temperature and humidity conditions, so the growers knew when to spray and when to remove infected vines.

Free T&D configuration software was included with each unit, expressly designed for ease of programming and downloading. The user-friendly, interface guided users quickly through data downloads and reconfiguring the datalogger, and also the free cloud software allowed growers to combine the readings of multiple loggers into a single display page.

Benefits

The greenhouse benefited in several short- and long-term ways from installing the T&D temperature and humidity data loggers. Most importantly, the TR-72wb’s provided constant temperature and humidity monitoring at high accuracy with customizable alarm settings. The T&D Temperature and Humidity Loggers made for an economic greenhouse fixture, as they were easily installed and retrieved by staff so that growers were able to get a comprehensive temperature and humidity profile of the environment and adjust conditions to obtain maximum healthy plant growth. Their programmable alarm feature was especially convenient when profiling the microclimate for disease prevention. The dataloggers worked easily in conjunction with the climate control system to verify its accuracy and measure the areas not covered by its fixed sensor. From transplantation to disease prevention, the entire growing process was modernized and correlated to further protect the crop, with all electronic recordings automatically stored in the cloud with easy download to local PCs for archiving. The TR-72wb’s also provided the technology to improve the growers’ documentation and understanding of the different temperature and humidity-sensitive processes at work, resulting in real cost benefits to the growers and a safeguarded high-quality crop.

As an additional precautionary option, the TR-72wb’s in concert with the WebStorage Service free cloud storage was configured to generate e-mail notification to alert the growers that temperature and humidity conditions had gone out of specification and corrections needed to be made immediately.

For further information on T&D Data Loggers, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or request more information.