Protecting High-Valued Material in Storage Devices

This guide is to show you how to be successful with continuous temperature monitoring in medical refrigerators and freezers. Cold storage is a common application in medical facilities across the board: hospitals, clinics, pharmacies and doctor’s offices. Accsense systems are ideal for medical monitoring and recording of these temperatures. These refrigerators range from high-quality medical units to common household-grade units.

The Problem:

Continuous temperature monitoring of storage materials is required in most medical facilities. If there were to be a temperature rise for a long period of time in the refrigerators or freezers this could cause the drugs or material being stored to become unusable, cost time and money to replace and in some cases be irreplaceable.

The Solution:

The following represent some of the issues experienced in monitoring refrigerators and freezers and solutions to these challenges.

The above is a typical Medical-Grade refrigerator with a digital display.

Why does the temperature of my unit vary over time?

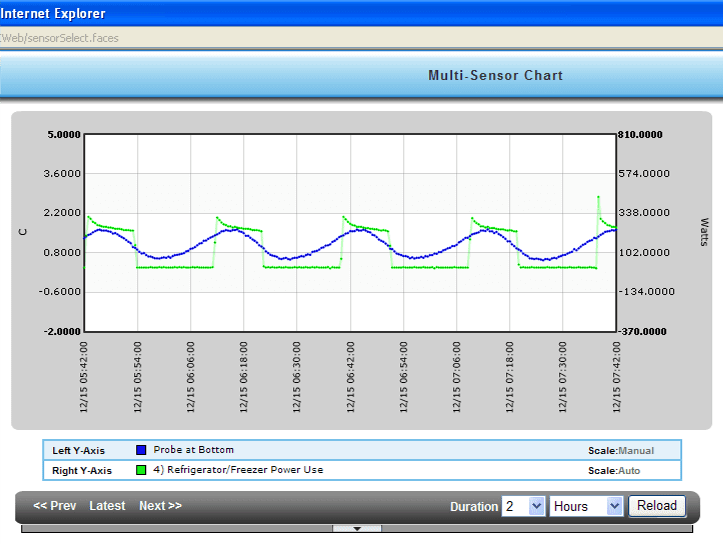

Graph showing refrigerator cavity temperature and refrigerator power consumption.

The temperature of the refrigerator or freezer cavity varies with time, and also depends on when the motor/compressor is running. Most often, refrigerator/freezer manufacturers slow down or “dampen” the response of their digital indicators to mask this variation, but it is real in all refrigerators and freezers, even medical grade units.

Should I use a probe thermal buffer?

The first issue is: “Do I use a probe thermal buffer or not?” A temperature probe buffer allows the monitoring system to measure the temperature of the refrigerator or freezer’s contents rather than the temperature of the air.

The above shows the temperature inserted into a thermal buffer.

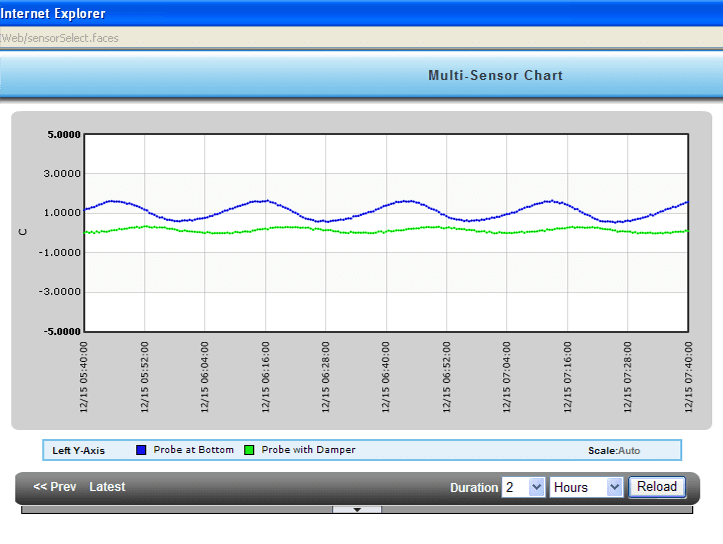

As shown below, the thermal buffer “smooths” out the temperature readings over time:

The above shows a refrigerator with two probes located side-by-side. The probe designated with the green line has a probe thermal buffer installed, the probe designated by the blue line has no thermal buffer installed.

The response will be slower with a thermal buffer, and fewer false alarms due to defrosting cycles and/or door openings will occur. The alarm limits can be set for a narrower range if required as well.

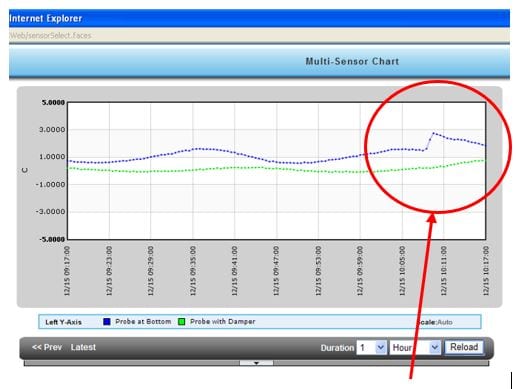

In the example below, note the difference in response to a door opening:

The above shows the response of two probes to a door opening. The probe with the blue line has no thermal buffer installed. The probe with the green line has a thermal buffer installed.

While the un-dampened probe reflects the immediate rise in temperature of the air in the refrigerator cavity, the probe with the thermal buffer reading more closely simulates the contents stored in the refrigerator.

Where Should I Locate The Probe?:

The next issue is probe location, or “Where do I put the probe”? First, the temperature inside the freezer is not uniform. The cold air enters the freezer from one location only and is measured by the thermostat at one location only, so a temperature gradient is sure to exist. There is no ONE temperature inside the freezer cavity.

Therefore, the answer is: “Somewhere secure, preferably towards the hinge side of the refrigerator.” Since there will be a temperature gradient inside the refrigerator cavity, there is no one “right” location. The most important aspect is that the probe does not move inside the refrigerator, so it gives a consistent reading and will not be disturbed by the normal access to the contents stored in the refrigerator.

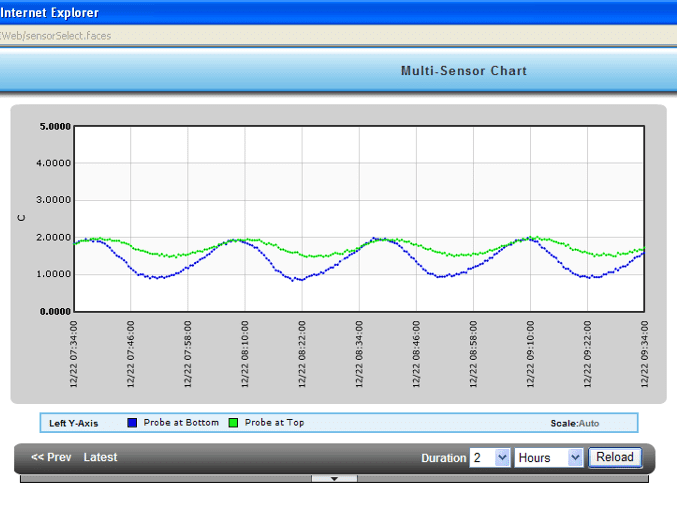

The above graph shows two probes in the same refrigerators cavity. The probe with the blue line is closer to the cold air entry, so it has a lower average temperature and cycles over a wider range.

Again, the most important factor is that the probe does not move once installed.

In Ultra-Low Freezer applications, an RTD temperature probe can be inserted into the cavity of the freezer through an access port at the back of the freezer, or through the door seal. If running the probe through the door seal, ideally, a hole is drilled in the door seal and plugged with Silicone Sealant, however, the door seal may be simply closed on the probe wire. In either case, the hinge side of the door is preferred for the greater leverage on the seal and the relative lack of potential disturbance on the hinge side. Note that closing the door seal on the probe wire may allow a small air gap which may increase frost build-up inside the freezer.

How often should I sample and record data?

Most organizations have specific recording periods which will dictate the recording intervals. Note that the Accsense system will synchronize these intervals to the clock, i.e. if data is recorded every 4 hours, it will occur exactly at midnight, 4am, 8 am, noon, etc. If there is no over-riding requirement, then recording every 2 hours is suggested.

How often should I check for an alarm?

The Accsense system can check for alarms at different intervals than those used to record data.

A typical setting for a medical refrigerator would be 10 minutes, with the trigger filter set to require 3 data points in a row to be out of limits before the alarm is triggered.

Why doesn’t the Accsense Monitoring temperature match my digital display exactly?

The temperature indicated by the digital display on the freezer may not match that of the Accsense system monitoring the temperature for two reasons. First, manufacturers of the freezers tend to use very slow-response temperature probes so that door openings do not set off any alarms. Second, the probes used by the manufacturer are often not even located inside the freezer cavity – they can be behind the back wall of the freezer (away from potential damage) and a “correction factor” applied electronically.

Due to the above, when calibrations are performed, the Accsense probe and the manufacturer probe must be placed very close together and the temperature allowed to stabilize over a sufficient time.

If required, the calibration parameters of the Accsense unit can be adjusted up or down, but this should only be done by qualified calibration personnel.

The Benefits:

The alarms generated by the system for each freezer can be sent to a customized phone or email lists, as it is common in many facilities for the “owner” of each freezer to be different.

The economic benefits of automated continuous temperature monitoring can also be taken into consideration. Compared to manual recording of the temperature that is required by regulatory agencies, automated monitoring is far cheaper. Consider the calculation below for a manual measurement:

- 1 minute per measurement multiplied by 6 measurements per day multiplied by 30 days per month multiplied by $20.00 per hour equals $60 per month! For a single freezer!

And that assumes that the facility is staffed 24 hours a day. If personnel must be brought in to monitor and record the temperature, the cost savings are even greater. By implementing a continuous refrigerator/freezer monitoring system, you also benefit by getting alerted to out of tolerance conditions so that you can prevent loss or damage to the stored material.

For wireless installations, extended-life battery packs are often a good idea, since 110v wiring is often limited in freezer rooms.

For more information on temperature monitoring systems, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or request more information.