Vibration Monitoring with Full Control Using ADwin

Vibration test stands are widely used in the automotive and aviation industry for testing parts in R&D and production lines. Typical test applications include endurance tests as well as the determination of dynamic frequency response characteristics. In this brief overview of vibration test stand control, we at CAS DataLoggers outline how a data acquisition and control system can be used to handle all the major needs of these applications.

Vibration test stands are widely used in the automotive and aviation industry for testing parts in R&D and production lines. Typical test applications include endurance tests as well as the determination of dynamic frequency response characteristics. In this brief overview of vibration test stand control, we at CAS DataLoggers outline how a data acquisition and control system can be used to handle all the major needs of these applications.

In these tests, parts or systems undergo testing with predefined Position, Force, Speed, or Acceleration stimulation. Common components under test include engine mountings, shock absorbers, wheel suspensions, exhaust pipes, seats, and steering parts. The excitation is measured and recorded by analog and digital sensors, while the resulting values from the test article are monitored simultaneously.

Test Stand Control Requirements

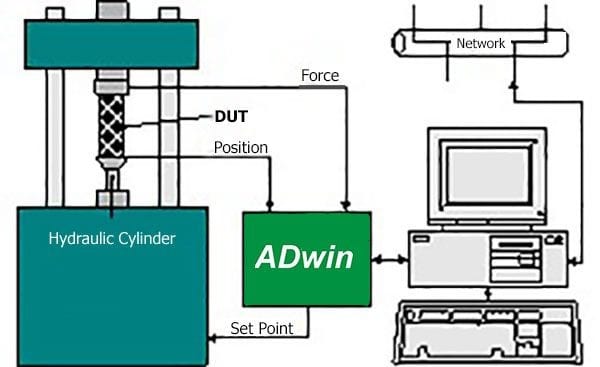

Control of the vibration test stand (in this example a single hydraulic axis) is usually performed by three main devices:

- A digital signal generator for the excitation setpoint curve, generating arbitrary, periodic, or transient waveforms in batch or continuous mode;

- A digital hydraulic closed-loop controller for tracking the setpoint values at the motion axis of the test stand, for superposition of peak and offset control, and for fast switching between Position and Force Control mode;

- A data acquisition system for online analysis of amplitude and phase response, dynamic characteristics evaluation, and limit value monitoring of signals from the device under test.

All these tasks can be executed on ONE ADwin data acquisition and control system, even for multi-axis test stands. ADwin systems simultaneously carry out open-loop and closed-loop control, waveform generation, and data acquisition and analysis. The PC receives the measurement data for visualization and storage purposes. Meanwhile, ADwin’s high-speed A/D converters allow sample rates of up to 50 MHz depending on the specific hardware in use, and the processing power handles signal evaluations and calculations for each sample.

All these tasks can be executed on ONE ADwin data acquisition and control system, even for multi-axis test stands. ADwin systems simultaneously carry out open-loop and closed-loop control, waveform generation, and data acquisition and analysis. The PC receives the measurement data for visualization and storage purposes. Meanwhile, ADwin’s high-speed A/D converters allow sample rates of up to 50 MHz depending on the specific hardware in use, and the processing power handles signal evaluations and calculations for each sample.

ADwin is an ideal solution for these applications as it contains its own real-time operating system enabling it to run independently of a PC. This way it can maintain the high accuracy a test bench application needs to ensure that components and systems are always delivered to specification. Processing of each measurement occurs immediately after acquisition thanks to ADwin’s onboard SHARC DSP. In this way, manufacturers are able to easily meet their specs and prove it to their customers using the data captured by ADwin.

In contrast, a DAQ system based on MS Windows can’t maintain this high timing accuracy due to the fact that Windows processors have to multitask while attempting to keep pace with calculations, i.e. they do not run independently of the PC as ADwin does. However additional tasks with “low” sample rates–less than 1 kHz–can be processed in parallel on the same ADwin system. Commonly this includes Temperature and Pressure monitoring or switching of valves and relays.

The Advantages of ADwin Solutions

ADwin is a highly flexible and cost-effective DAQ solution for the control of all kinds of vibration test stands. At CAS DataLoggers our customers especially appreciate its operational reliability even when used together with a Windows PC.

The fast control tasks run on ADwin’s dedicated real-time processor. The graphical user interface runs on the PC and can be quickly designed since virtually all common software development tools have easy access to the ADwin system and the data.

For example, the ADwin-Light-16 Real-Time Data Acquisition and Control System enable real-time development in a test bench setup. This data acquisition and control solution records highly accurate test data and can operate in real time, making calculations as each measurement is processed. The ADwin-Light-16 system features 8x 16-Bit analog inputs, 2x 16-bit analog outputs, and 6x TTL/CMOS compatible digital inputs and outputs. The system also utilizes a local 32-Bit SHARC DSP with its own local memory to handle system management, data acquisition, online processing, and control of outputs. Several system configurations are available including those with USB or Ethernet communications.

ADwin systems can also be used with a touchscreen Maple display to provide real-time viewing and intuitive control. The optional Ethernet port allows the PC to connect to the in-house network for data storage, transfer, and printing.

ADwin System Functions

- Intelligent Data Acquisition

- Digital PID Feedback Control

- Signal Generators: Sinewave, Ramp, Noise, Sweep, Pulse, Step

- Dynamic characteristics evaluation

- Hardware-in-the-Loop

- Digital Filtering

- Complex Trigger Conditions

- Min/Max, Average, RMS

- Statistics, Correlations

- Integrals, Derivatives

- FFT, Amplitude, and Phase Response

Test Operation

During test execution, ADwin automatically captures real-time test data from sensors and graphs the data on a display. For example, during the sequence ADwin can automatically collect pressure data and display the information while also performing control tasks such as actuating relays. The ADwin can also calculate factors for the cycle’s data set such as surge peak pressure, shock factor, and pass/fail information. Throughout the test, users can refer to a status bar displaying the cycle, the portion of the data being displayed, and all valve settings for that data set.

Modular Design

For a modular design, ADwin Pro-II DAQ systems offer data acquisition modules with interfaces for MIL-STD-1553 and ARINC-429 standards, providing access to these two widespread avionic data protocols. For the MIL bus, the SMT bus monitor is available. The ARINC interface offers one transmitter and two receivers which can be operated at the same time. Additionally, the new SENT module enables automotive electronic applications and can evaluate 4 SENT signals (fast channel and slow channel) in parallel.

Data Acquisition Software

ADwin’s included ADbasic software defines the processing sequences executed on the hardware and enables the programming of mathematical operations and functions which are executed immediately after each sampling step. Using ADbasic, users can optimize and compile program code with just a click of the mouse. After being loaded on the system by ADbasic or a graphical PC user interface, the real-time processes execute independently. A library is included with standard functions such as filtering, various examples for counter use, closed-loop controllers, function generators, etc. which result in faster program implementation.

Generate Graphs and Reports

ADwin can generate detailed graphs plotting test data such as Time and Pressure. During the test, users can also view test data in numeric or graphical form. Test results can be stored in a data file and are also available as a final report that can be printed when the test is complete, giving all of the test results. Likewise, specific part information can be stored in a file together with Part Serial Numbers, Cycle Timing, Part Limits, etc.

Value-Added Support

CAS DataLoggers can help your business design and assemble a test stand application for your unique requirements. We can provide measurement instrumentation, programming, testing, and onsite training. As a real rarity in this industry, our Inside Engineering Dept. can also provide free technical support.

Jumpstart Your Test Application Today!

With their simple hardware architecture, ADwin systems are the first choice for modernizing vibration test stands. ADwin systems have been used since 1988 in the implementation of both new and modernized test stands. Thousands of different test stands have been built or modified based on an ADwin-to-PC solution. At CAS DataLoggers we have extensive experience with ADwin products for hydraulic test applications— give us a call today to learn more!

For further information on ADwin Data Acquisition and Control Systems, vibration test stands, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.