Cheese Process Monitoring and Optimization With a Single dataTaker System

A major dairy product manufacturer monitoring cheese-shaping machines on the production line required a cheese process monitoring solution. Like many others of its kind this facility is heavily automated and requires precise machine timing to achieve its production targets. The plant uses a Programmable Logic Controller (PLC) to drive the valve sequencing for its machinery. The system is designed to produce 3000 kg of product per hour, but in practice, it is unable to achieve this rate. In order to increase profitability, the plant saw the need for a data logging solution to determine where the PLC algorithms could be optimized to meet its quotas.

A major dairy product manufacturer monitoring cheese-shaping machines on the production line required a cheese process monitoring solution. Like many others of its kind this facility is heavily automated and requires precise machine timing to achieve its production targets. The plant uses a Programmable Logic Controller (PLC) to drive the valve sequencing for its machinery. The system is designed to produce 3000 kg of product per hour, but in practice, it is unable to achieve this rate. In order to increase profitability, the plant saw the need for a data logging solution to determine where the PLC algorithms could be optimized to meet its quotas.

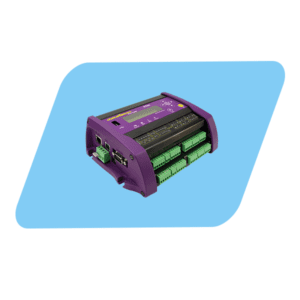

After speaking with a CAS DataLoggers Applications Specialist, the plant installed a dataTaker DT80 Intelligent Data Logger. The dataTaker DT80 is a cost-effective data logger expandable to 100 channels, 200 isolated, or 300 single-ended analog inputs. Capable of low-power operation, the stand-alone DT80 can scale and log nearly any physical value at 18-bit resolution, connecting to most sensors and data measurement sources. The DT80’s built-in display shows current readings, while dataTaker’s ease of use enables operators to group sampling, logging, alarm, and control tasks within schedules to fit their needs.

The plant’s engineer wired the dataTaker DT80 to monitor and record the output states of the PLC, specifically to record the time and valve state whenever a valve is opened or closed. The DT80 also records the number of cycles of each cheese-shaping machine. This is achieved by connecting the control lines to the DT80’s digital inputs, which continually monitor these lines for any changes in digital states. The dataTaker’s Modbus slave and master functionality allows connection with Modbus sensors and devices and to SCADA systems. The dataTaker’s smart serial sensor channels can interface with RS232, RS485, RS422, and SDI-12 sensors.

The DT80 can store approximately 10 million data points, which is large enough to be able to record high-speed digital states of PLCs for extended periods of time. Users can also choose to overwrite or stop logging once this allocated memory is full. The data logger also includes USB memory stick support for easy data and program transfer. This way users can make changes to the logger’s programming on the fly or update the firmware without having to connect the dataTaker to a PC. The datalogger’s built-in web and FTP server give users remote access to logged data, configuration, and diagnostics.

The DT80 can store approximately 10 million data points, which is large enough to be able to record high-speed digital states of PLCs for extended periods of time. Users can also choose to overwrite or stop logging once this allocated memory is full. The data logger also includes USB memory stick support for easy data and program transfer. This way users can make changes to the logger’s programming on the fly or update the firmware without having to connect the dataTaker to a PC. The datalogger’s built-in web and FTP server give users remote access to logged data, configuration, and diagnostics.

The recorded data can be presented as a state machine that shows the exact timing of each valve. From this, the variations of each machine can be determined and the valve sequencing optimized in the PLC algorithm. This will in turn allow the manufacturer to increase cheese production to reach their 3000kg targets and increase profitability. Throughout, dataTaker’s rugged design and construction provide the plant with reliable operation even under extreme industrial conditions.

The dataTaker graphical interface—dEX—is included FREE with the datalogger and uses a pre-installed Windows Explorer-style interface enabling quick setup and configuration. Users configure and run dEX directly from a web browser, accessible either locally or remotely over the Internet. Any of the logger’s built-in communications ports can be used to view dEX, including Ethernet, USB, and RS-232.

This application is just one example of many showing how a smart data logger can be paired with a PLC to accomplish complex tasks and solve business-critical timing problems. Using the dataTaker to keep watch over the PLC’s data, users can optimize production with just a single system. Both hardware and software are easy to use even for novices, enabling a quick start to this and many other industrial monitoring projects.

For more information on the dataTaker DT80 Intelligent Data Logger, or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.