Control Shot Injection with an ADwin Gold System

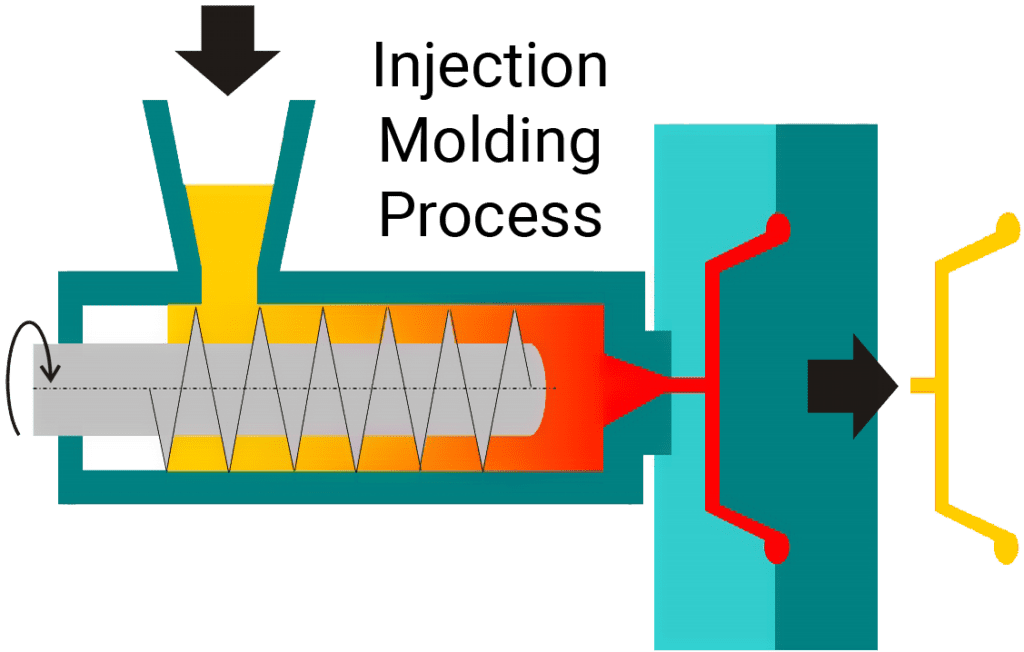

CAS DataLoggers interviewed a long-time customer using an ADwin-Gold Real-Time Data Acquisition & Control System for injection molding process monitoring. Read on to learn how his plastic injection molding business has benefitted from high-speed data acquisition—and how your business can do the same.

Q&A Session

Q: You have been using the ADwin Gold system for plastic injection molding process monitoring of your equipment for several years now, how do you use it for your casting process?

A: We use our ADwin in two different modes:

- Monitoring the shot injection for quality control.

- Controlling the shot injection to maintain part consistency.

Q: What is it about ADwin that makes it suitable for your application?

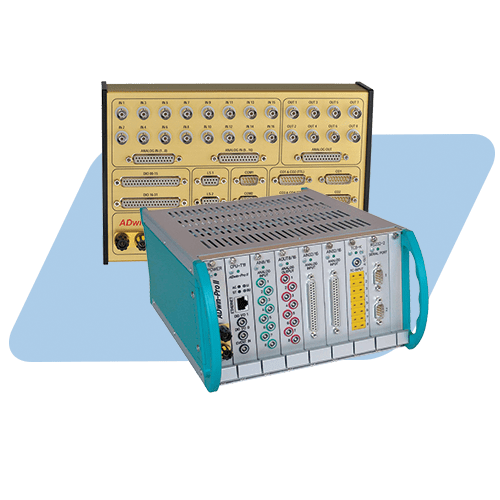

A: ADwin is easy to interface with our Visual Basic Man-Machine Interface application. The system is programmable, allowing us to customize its real-time control interaction through its analog and digital I/O. The ADwin Gold processor is very fast which gives us very high precision in the instrument. There is a lot of onboard memory so it can collect an entire shot’s worth of data locally.

Q: Have you considered any other commercially-available products in the past?

Q: Have you considered any other commercially-available products in the past?

A: Years ago we designed a completely custom solution using the STD bus and standard logic components. For many years before switching to ADwin we had been using a custom solution provided to us by Visi-Trak Corporation.

Q: What advantages can an injection molding machine maker gain by using ADwin instead of their present controller or PLC?

A: Complete control over the I/O to the hardware level gives us very precise operation. With reaction time down in the sub-microsecond range, the ADwin can control the machine better than anything out there. ADwin has increased our yield and reduced scrap rates immensely.

ADwin Can Do The Same For Your Application

For real-time data acquisition and control, ADwin systems have a fast Sample rate of 100kHz aggregate, to 1.25 MHz per channel. All measurements are made at true 16-bit resolution. Gain competitive advantage from faster sampling and control:

- Extremely fast response time of under 1 micro-second;

- High-speed PID loops—up to 100 kHz with real-time processing;

- Tightly coupled Integrated Analog in/out and Digital in/out plus counter/timer channels

ADwin data acquisition systems offer all the benefits of a direct software connection with Windows without the risk of OS lockups and crashes. The ADwin’s onboard local DSP operates in real-time independently of the Windows CPU, so that the system will continue to run even if the PC stops. Users have full application development freedom with ADwin’s full set of available drivers for many of the popular programming environments including VB, VC/C++, LabVIEW, TestPoint, and others.

This provides for full integration with other applications and programming languages. ADwin also has intuitive development tools with support for up to 10 prioritized processes. A wide variety of communications options are available—Ethernet or USB for PC communication, CAN-bus, and RS232/485 as well as the most popular Filedbuses.

ADwin’s product family offers multiple form factors:

- Plug-in board

- Encased stand-alone

- Modular rack mount systems

Optional Stand-alone operation:

- An available boot loader option allows for full-function operation independent of any PC or external computer. Users can augment their PLC installations with a high-speed, quick response-time system.

High-Speed DAQ for Process & Test Control

ADwin systems are ideal for many different applications including:

- Die Cast Machine Process control, PID during the injection cycle (high-speed control of Pressure, Flow, and Volume)

- Crack Growth measurement system—Hardware & Software for adaptive/predictive PID control of hydraulic test equipment (for testing valves, hose fittings, etc.)

- Stamping press force measurement for predictive failure analysis

- Machine vibration, early fault identification

- Signal generation and signal processing applications

For more information on ADwin systems, injection molding process monitoring, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.