Accsense VersaLog Multi-Channel Temperature Recorders

Ensuring the pet food manufacturing process meets FDA requirements, manufacturers must monitor the temperature of their extruding equipment to document the food is properly processed and safe.

Ensuring the pet food manufacturing process meets FDA requirements, manufacturers must monitor the temperature of their extruding equipment to document the food is properly processed and safe.

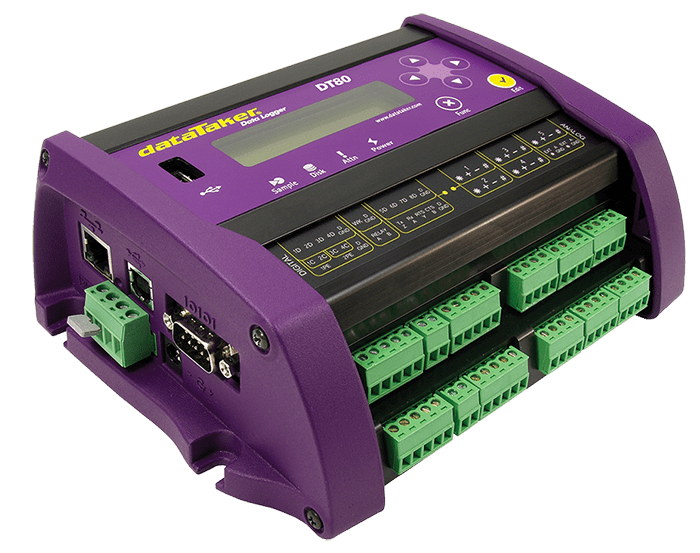

A CAS DataLogger customer held to these requirements wanted to log and monitor the temperature of the product as it exited the extruder. They also wanted to have access to the data from multiple sites from a single, corporate location. The dataTaker DT80 was selected for the solution. With the ability to accept 10 two-wire differential analog inputs, each DT80 could monitor up to 4 extruders.

Installation

A thermistor was installed to monitor the temperature of the food in the pet food manufacturing process as it exited each machine. The data was recorded to satisfy regulatory requirements and show that the extrusion occurred at an appropriate temperature to prevent bacteria growth. A digital output of the DT80 was wired to an industrial I/O module which would activate a diverter to redirect the food to a scrap container if the temperature fell below the acceptable threshold.

Usage

A program was written for the data logger to record the data at 1-minute intervals. Each machine was monitored independently to aid in data management. An alarm was configured to compare the measured temperature against the threshold and activate a digital output on the logger if the temperature fell below the acceptable temperature.

A program was written for the data logger to record the data at 1-minute intervals. Each machine was monitored independently to aid in data management. An alarm was configured to compare the measured temperature against the threshold and activate a digital output on the logger if the temperature fell below the acceptable temperature.

Data was stored to the internal memory of the data logger, then periodically transferred to a USB stick and archived on a separate server. The USB stick also allowed for easy programming changes and firmware updates without connecting to a PC.

Benefits

Using this designed solution, the manufacturer has been capable of continuous documentation for their production process to ensure that all products that leave the facility are safe and meet all FDA standards. CAS Dataloggers provided training and configuration assistance for the System Integrator who handled the implementation in 15 plants across the country. For further solutions for data logging and monitoring for temperature critical applications, contact a CAS Data Logger Solution Analyst for application-specific designs. Pricing will be based on individual application needs and required results.

For more information on dataTaker Intelligent Universal Input Data Loggers, the pet food manufacturing process or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.