Delphin DAQ Systems

CAS DataLoggers provided a remote data acquisition solution for a state-owned oil and gas company located in Eastern Europe involved in developing natural gas in distant gas fields. The gas came out of a wellhead for processing in either of the two dehydration plants. These plants extract water from the gas before sending it through a compressor station and then pumping it through the pipeline system. However, since the two natural gas dehydration plants were based in a remote location, the company needed a standalone data acquisition and logging system to record production and process data from the plant and also to gain access to all recorded data. This system would have to be able to perform high-precision measurements and also feature sophisticated alarm and programming capabilities enabling the device to process measurements and initiate actions on its own.

CAS DataLoggers provided a remote data acquisition solution for a state-owned oil and gas company located in Eastern Europe involved in developing natural gas in distant gas fields. The gas came out of a wellhead for processing in either of the two dehydration plants. These plants extract water from the gas before sending it through a compressor station and then pumping it through the pipeline system. However, since the two natural gas dehydration plants were based in a remote location, the company needed a standalone data acquisition and logging system to record production and process data from the plant and also to gain access to all recorded data. This system would have to be able to perform high-precision measurements and also feature sophisticated alarm and programming capabilities enabling the device to process measurements and initiate actions on its own.

Installation

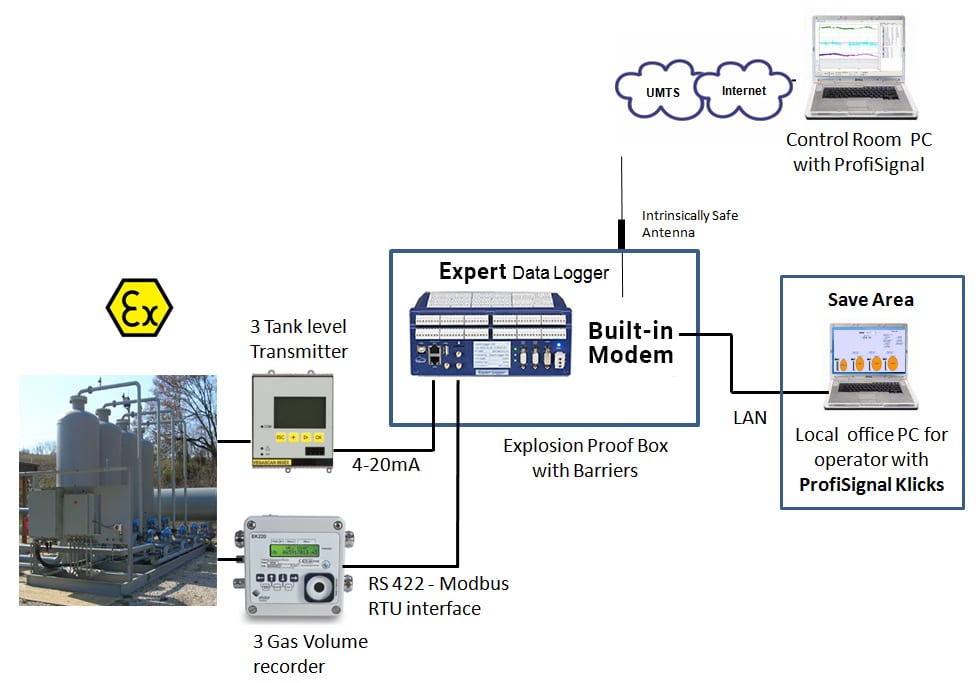

Plant management decided to install a Delphin Expert Logger 100 Data Acquisition System in each of the two dehydration plants. The Expert Loggers were outfitted with optional UMTS/LTE cellular modem cards to provide remote access functions. Since these systems were located in hazardous areas, each unit was fitted inside an explosion-proof box outfitted with EX safety barriers. The Expert Loggers were interfaced to 3 tank level transmitters using a 4-20mA analog output signal and also to 3 gas volume conversion devices from VEGA through an RS-485 Modbus interface (see Figure 1).

The Expert 100 Logger system offers analog 16 inputs capable of measuring a range of sensors including RTD’s and thermocouples plus voltage or 4-20 mA signals, enabling any physical value to be acquired as needed. Accurate measurement of 4-20 mA signal from the tank sensors was made using the logger’s 24-bit resolution A/D converter which was then scaled appropriately. The Expert Logger also offers multiple serial communications ports capable of RS-232 or in this case RS-485 with Modbus RTU. Data on gas flow and the total volume was easily acquired from multiple registers in each gas volume recorder and stored in memory along with the level data. The Expert Logger was equipped with 16 GB of internal memory allowing many months of data to be stored locally.

Usage

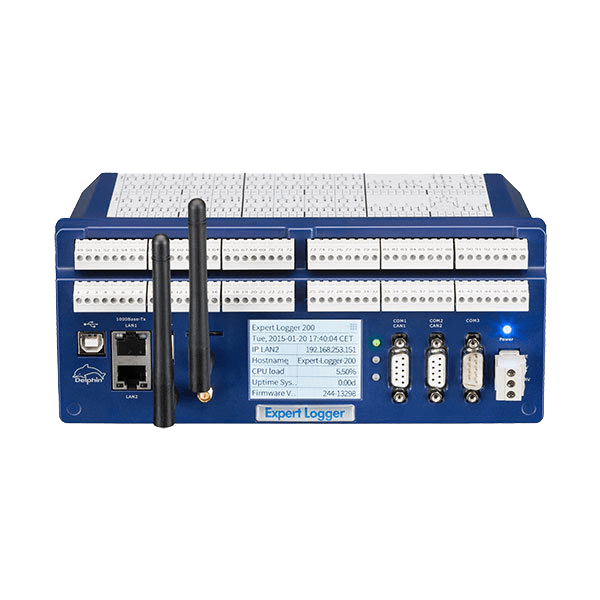

Ideal for many different data logging, remote data acquisition, and testing applications, Delphin Expert Loggers perform tasks in the fields of process technology, test engineering, remote monitoring, and research and development, offering quick and reliable data acquisition from analog, digital, and serial signals. It features standard Ethernet and USB interfaces for connection to a PC plus optional WiFi and UMTS/LTE cellular modems. In addition to Modbus RTU, it supports SDI-12, Modbus TCP, CAN 2.0, and OPC UA interfaces. For applications that require a large number of analog or digital I/O points, expansion slave modules can be added via the CANbus. Screw terminal connections provide secure connections and reliable operation. Additionally, the Expert Loggers’ small size of 210 x 125 x 80mm simplified installation in the explosion-proof enclosure.

The dehydration plant operator based outside the hazardous area had a local monitoring PC running Delphin’s ProfiSignal software. ProfiSignal offered a user-friendly development system for programming the data recording and reporting functions with no specialized IT knowledge required. The software also contained functions for automating processes and generating user-defined reports. Operators used the software’s user-configurable dashboard to monitor plant performance. Utilizing the built-in UMTS/LTE modem with a secure VPN connection, the control room operator at the head office had remote access to live data and data downloaded from the system memory. Additionally, the data retrieval could be automated by using the scheduler function of the DataService Configurator.

The dehydration plant operator based outside the hazardous area had a local monitoring PC running Delphin’s ProfiSignal software. ProfiSignal offered a user-friendly development system for programming the data recording and reporting functions with no specialized IT knowledge required. The software also contained functions for automating processes and generating user-defined reports. Operators used the software’s user-configurable dashboard to monitor plant performance. Utilizing the built-in UMTS/LTE modem with a secure VPN connection, the control room operator at the head office had remote access to live data and data downloaded from the system memory. Additionally, the data retrieval could be automated by using the scheduler function of the DataService Configurator.

Benefits

The oil and gas company gained several benefits from installing the Delphin Expert Logger remote data acquisition system in each of its two dehydration plants. The system, equipped with the UMTS/3G modem, served as an effective solution for this application with the ability to measure analog signals and serial devices. Additionally, the Expert Logger’s compact size made the system easy to install in the explosion-proof box to guarantee its safety. The system includes many serial interface standards so that VEGA Scan EK220 volume conversion units can be interfaced. The powerful ProfiSignal software was used to develop an operator user interface, including dashboards, and also added reporting functions.

For further information on the Delphin Expert Logger Data Acquisition System, other devices in the Delphin product line, remote data acquisition, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.