Collecting Data To Improve & Maintain Designs

One of the main challenges for structural engineers is to not only assure the safety of critical structures but also to maintain and improve them. Data loggers play a crucial role in collecting data for Structural Health Monitoring, enabling engineers and scientists to validate their designs with the deployment of sensors for long-term testing and monitoring. In this process, real-world data is acquired, recorded and analyzed to help provide safe environments for users. This information greatly enhances the ability to detect and address damage before catastrophic failure occurs.

One of the main challenges for structural engineers is to not only assure the safety of critical structures but also to maintain and improve them. Data loggers play a crucial role in collecting data for Structural Health Monitoring, enabling engineers and scientists to validate their designs with the deployment of sensors for long-term testing and monitoring. In this process, real-world data is acquired, recorded and analyzed to help provide safe environments for users. This information greatly enhances the ability to detect and address damage before catastrophic failure occurs.

Sensors

The sensing technologies and the data logger that are used need to be capable of detecting changes that may indicate the structural hazards and report the data accordingly. Engineers then define the health and life of a structure according to the data captured by the data logger from these sensors.

Most commonly used sensors in structural health monitoring are strain gauges – both resistive and vibrating wire, force and torque sensors, displacement sensors and temperature sensors. If any of the measured data indicates a hazard, either actual or potential, a repair & remediation schedule is planned accordingly.

The structural health monitoring process involves the observation of a system over an extended period of time, using periodically sampled response measurements from an array of sensors. The current state-of-system health is determined by extracting data that highlights damage-sensitive information from these measurements and performing statistical analysis of these features.

Monitoring Process

Over the long term, data analysis increases visibility into the ability of the structure to perform its intended function. After extreme events, such as earthquakes or blast loading, structural health monitoring is used for rapid condition assessment with the aim to provide reliable, real-time information regarding the integrity of the structure. Structural health monitoring can be applied to fixed infrastructure, such as building and bridges, or mobile infrastructures, such as ships, airplanes, and trains. This concept is widely applied to various types of infrastructure projects, especially as countries all over the world enter into an even greater period of construction, ranging from freeways and tunnels to airports and skyscrapers. Where damage to critical structures is concerned, it is important to note that there are multiple stages of increasing difficulty in the monitoring process, that require the knowledge of previous stages, namely:

- Detecting the existence of the damage on the structure

- Locating the damage

- Identifying the types of damage

- Quantifying the severity of the damage

It is often necessary to employ signal processing and statistical classification to convert raw sensor data on the infrastructural health status into damage information for assessment.

Elements of Structural Health Monitoring Systems include the primary structure, sensors, and data logging systems, data transfer, data management, data analysis, and interpretation and diagnosis.

An example of this technology is embedding sensors in structures like bridges. These sensors provide real-time monitoring of various structural changes like stress, strain, and displacement. In the case of civil engineering structures, the physical quantities measured by the sensors acquired using a data logger. With the aid of an intelligent data logger, real-time feedback on the structures based on the information from sensors is possible.

Summary

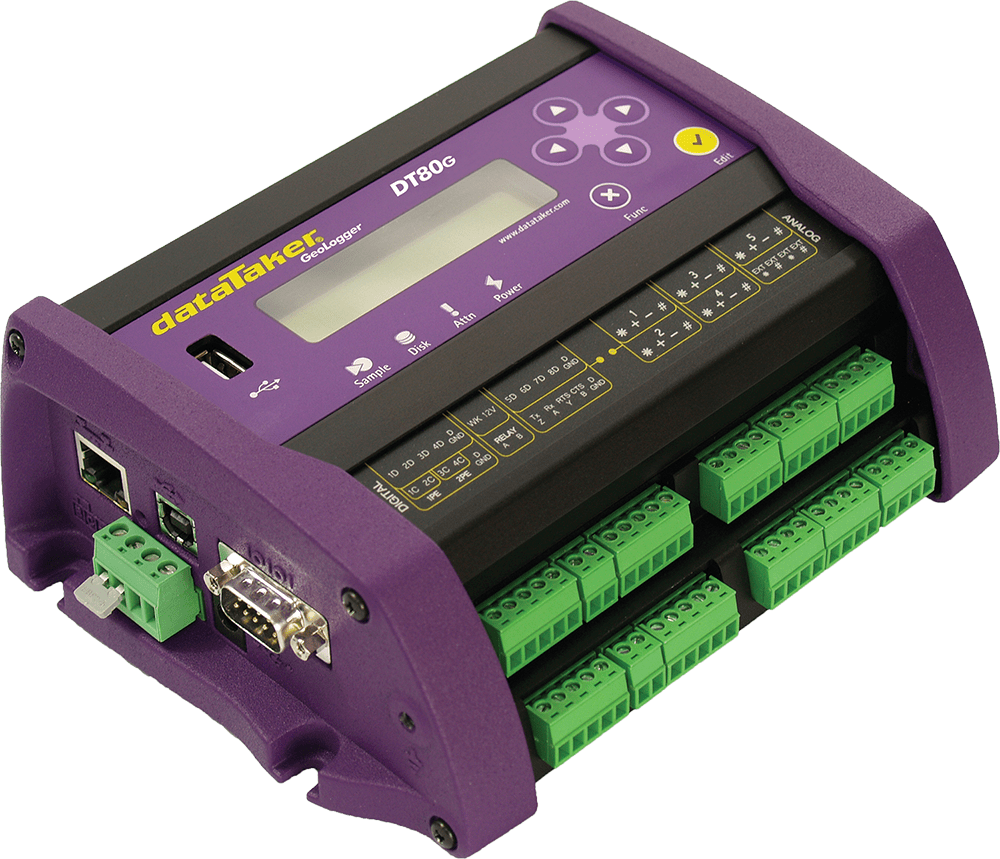

DataTaker Geo loggers are designed specifically for structural monitoring with vibrating wire technology. They are compatible with the majority of the commercially available geotechnical sensors. In addition, their universal analog inputs allow connection to many other types of common sensors to measure temperature, voltage, current and resistance. With extensive built-in processing capabilities, these loggers can perform scaling, sensor compensation and statistical analysis to simplify the structural health monitoring process. Lastly, an on-board, graphical, web-based interface makes them easy to use.

For further information on the dataTaker Geo Loggers, structural health monitoring, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.