Squirrel Data Loggers Monitor Sugar Beet Processing

CAS DataLoggers provided the data logging solution for UK sugar company British Sugar, which was searching for a high-tech way to prevent their sugar beet storage stock from deteriorating while waiting to be processed into white sugar bound for kitchens and tables around the world. Harvested sugar beets remain alive and as they respire, converting sugar into carbon dioxide and water, they generate heat. If the temperature inside a mountain of sugar beets—called a clamp –rose above 10°C (50°F), there was a dramatic increase in sugar loss.

CAS DataLoggers provided the data logging solution for UK sugar company British Sugar, which was searching for a high-tech way to prevent their sugar beet storage stock from deteriorating while waiting to be processed into white sugar bound for kitchens and tables around the world. Harvested sugar beets remain alive and as they respire, converting sugar into carbon dioxide and water, they generate heat. If the temperature inside a mountain of sugar beets—called a clamp –rose above 10°C (50°F), there was a dramatic increase in sugar loss.

The crop could be stored for 60 days before processing, but if poorly stored, sugar beets could lose up to 60% of their sugar content before they were processed, and whole clamps could lose 1% of their sugar content a day. Additionally, while the inside of a poorly maintained clamp could be generating considerable heat, the surface exposed to the elements could be frozen, leading to a further loss of sugar content. The goal was to establish and maintain a well-ventilated, cool clamp in a hostile and often exposed farmyard environment where temperatures could fluctuate between 15°C (59°F) during the day to -10°C (14°F) at night. Seeking to minimize sugar loss and maximize their product quality, British Sugar needed a highly-accurate data logging solution that could easily be inserted throughout a clamp to help them experiment with innovative storage techniques.

Installation

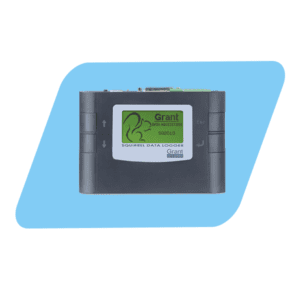

The customer installed 6 modified Grant Squirrel 2010 Universal Input Data Loggers into widespread areas of its test clamps. A powerful yet portable data logger designed for versatility and ease of use, the Squirrel 2010 features 4 to 8 universal analog inputs measuring current, voltage, resistance, and temperature, along with 8 digital inputs. 2 alarm outputs and 2 pulse counter inputs are also standard, with measurements made at a basic accuracy of 0.1% and an operating temperature of -20°C to 65°C (-4°F to 149°F).

The customer installed 6 modified Grant Squirrel 2010 Universal Input Data Loggers into widespread areas of its test clamps. A powerful yet portable data logger designed for versatility and ease of use, the Squirrel 2010 features 4 to 8 universal analog inputs measuring current, voltage, resistance, and temperature, along with 8 digital inputs. 2 alarm outputs and 2 pulse counter inputs are also standard, with measurements made at a basic accuracy of 0.1% and an operating temperature of -20°C to 65°C (-4°F to 149°F).

The Squirrel’s handheld, compact design made for a truly portable solution for employees scaling the clamps and had an extended battery life for long periods of unattended logging. Large amounts of experimental data were collected, with each logger storing up to 1.8 million readings.

The economical Squirrel 2010s were built to withstand the worst possible conditions, including the wild temperature fluctuations in the exposed farmyard and heavy rains. Regardless of the weather, the Squirrels provided British Sugar researchers with detailed and precise temperature measurements every hour.

Usage

The Squirrel 2010 portable data loggers were infinitely adaptable and simple to operate. Easily programmable via four integral push buttons and large graphical display, the Squirrel data loggers were capable of many routine data logging tasks, including more demanding applications requiring up to 10 readings per second on one channel. The temperature data could be instantly downloaded onto a conventional PC via USB connectivity in an easy-to-analyze graphical form. USB or RS-232 communications options were also available.

British Sugar looked closely at how sugar loss was affected by temperature and tested several new methods of controlling temperatures throughout the beet clamps. The data from the Squirrels enabled researchers to experiment with a variety of plastic and poly felt materials to insulate their clamps from the worst of the weather and with building effective ventilation shafts directly into the clamps to keep them cool.

Each Squirrel 2010 data logger came equipped with free SquirrelView software to enable company researchers to import data onto a PC and display detailed graphs or print them out for record purposes. SquirrelView’s intuitive, user-friendly, spreadsheet-style interface allowed for quick set-up of the data loggers, speedy data downloads, and direct export to Excel. Upgrading to SquirrelView Plus gives additional benefits such as graphical data analysis and advanced reporting options.

Each Squirrel 2010 data logger came equipped with free SquirrelView software to enable company researchers to import data onto a PC and display detailed graphs or print them out for record purposes. SquirrelView’s intuitive, user-friendly, spreadsheet-style interface allowed for quick set-up of the data loggers, speedy data downloads, and direct export to Excel. Upgrading to SquirrelView Plus gives additional benefits such as graphical data analysis and advanced reporting options.

Benefits

British Sugar realized several major benefits after installing the SQ2010 data loggers in their sugar beet storage grounds. The portable and compact loggers were essential for recording highly accurate measurements throughout the clamps’ interior and exterior, and their proven durability kept them recording despite the harsh weather. Following the successful temperature-control experiments, more efficient storage methods were developed resulting in extending the amount of time the company had to process the annual crop from 110 days to 150 days. Those extra 40 days greatly enhanced the cost-effectiveness of the process and gave the company a big advantage; across Europe, sugar processors were still locked into processing their stores of sugar beets within 110 days to avoid major deterioration of the crop. Furthermore, the data logged on the Squirrel data loggers provided the basis for advice to farmers across the country on the most effective methods of storing sugar beets before processing.

Patrick Jarvis of British Sugar remarked: “This research is vital, not only giving us a competitive edge, but also ensuring that British farmers get the best return from their beet crop. The Squirrel data loggers are extremely robust and accurate, and the data they provide is easy to download and easy for our field researchers on farms to analyze. The Squirrels are playing a vital part in keeping us ahead of our European competitors.”

For more information on Grant Squirrel Loggers, or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Applications Specialist at (800) 956-4437 or request more information.