Delphin Expert Vibro System Diagnoses Faults

Delphin Technology provided the vibration monitoring solution for Femaris, a Romanian company focusing mainly on providing products and services for measuring and analyzing technical parameters. Femaris offers complete solutions for the implementation of predictive and proactive machine maintenance, as well as online and offline monitoring of critical operational parameters. This includes static and dynamic balancing of rotors, data acquisition systems to record vibrations and noises, and service including training of personnel. CAS DataLoggers, a Delphin distributor, presents this Applications Note showing how Femaris supplied its own customer with a Delphin system to assist as a vibration monitoring system for hydro turbines.

Delphin Technology provided the vibration monitoring solution for Femaris, a Romanian company focusing mainly on providing products and services for measuring and analyzing technical parameters. Femaris offers complete solutions for the implementation of predictive and proactive machine maintenance, as well as online and offline monitoring of critical operational parameters. This includes static and dynamic balancing of rotors, data acquisition systems to record vibrations and noises, and service including training of personnel. CAS DataLoggers, a Delphin distributor, presents this Applications Note showing how Femaris supplied its own customer with a Delphin system to assist as a vibration monitoring system for hydro turbines.

Application

Femaris required a solution for its customer HIDROELECTRICA SA, Romania’s main electrical producer. The company is divided into several divisions defined by geographic location. HIDROELECTRICA has an installed generating capacity of 6438 MW and produces approximately 30% of the entire electrical power in Romania. This particular Delphin vibration monitoring system was implemented in Hidroelectrica Oradea SA.

Technicians at Hidroelectrica noticed a suspect sound originating from the generator of a turbine, a sound believed to be caused by vibrations within the hydro turbine. Because of this situation, they required vibration measurement.

To discover the source of this sound, their main objective was to install an easily-configurable real-time vibration monitoring system to improve fault prediction and let them identify corrective actions before damage to the turbine.

Also, the system had to be modular so that it could be extended in the future, for example, to make absolute vibration measurements with piezoelectric accelerometers. The customer decided to install a Delphin Expert Vibro Data Acquisition and Control System along with Delphin ProfiSignal software to monitor and perform the following

-

- Vibration at multiple locations on the turbine – peak-to-peak displacement

- FFT analysis of the vibration signals

- Smax parameter

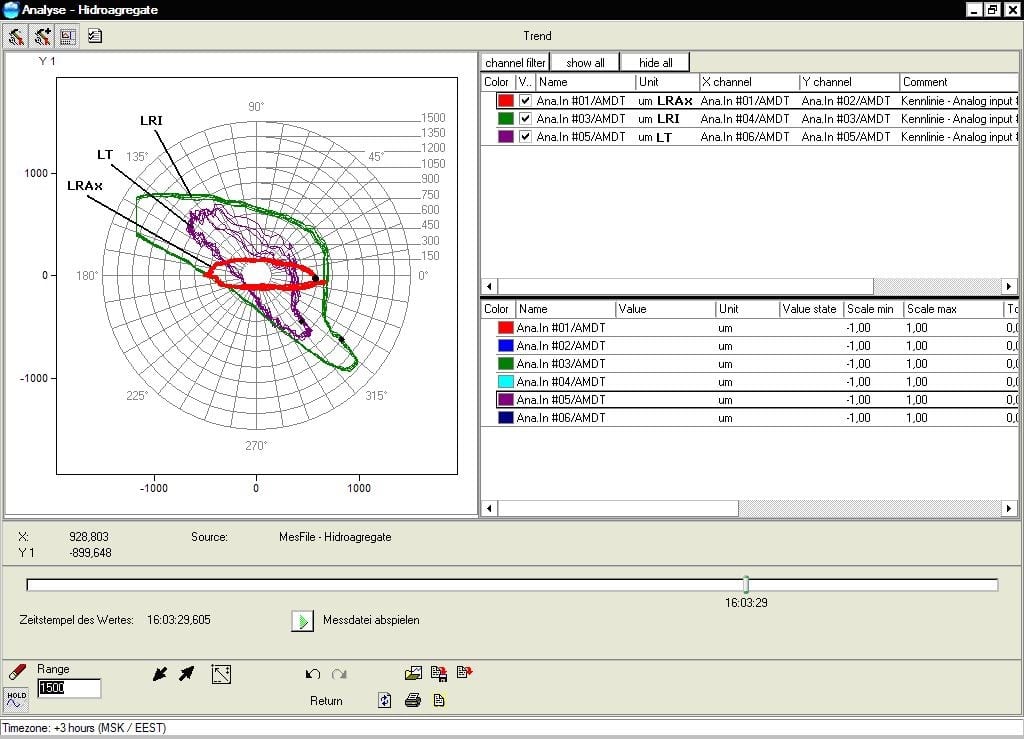

- Orbit diagrams

- Provide Trend analysis functions

Technical Conditions

ISO 7919-5:2005 Mechanical vibration, Evaluation of machine vibration by measurements on rotating shafts. Part 5: Machine sets in hydraulic power generating and pumping plants ISO 10817 Rotating shaft vibration measuring system

Measurement direction: Radial in two directions X – Y with two proximity transducers mounted orthogonally to each other

Measured parameters: Relative vibration of the journal bearing

Measuring unit: Peak-to-peak displacement of vibration [µm] for the distance between the sensor and shaft

Analyzed machine: Hydro turbine Vertical Kaplan, 10 MW power.

Monitored journal bearings:

- Turbine bearing – LT

- Inferior radial bearing – LRI

- Axial radial bearing – Lrax

Solution

For this application, Femaris recommended the following components:

- Delphin Expert Vibro device

- Direct input of piezoelectric accelerometers (for shaft/bearing vibration monitoring & analysis)

- Voltage divisor

- Proximity systems – Transducers with conditioner

- Delphin ProfiSignal Basic software with Vibro option (enables real-time FFT processing and analysis)

Here the necessary vibration measurements were performed with proximity systems mounted on all three journal bearings of the turbine. Two transducers were mounted on each journal bearing, with a radial direction and at an angle of 90° between them.

The Expert Vibro was mounted within a portable electrical panel. The customer requested that the system must be portable to be mounted on different hydro turbines that presented electrical or mechanical faults.

The software used for fault diagnostics is ProfiSignal Basic and ProfiSignal Vibro. Following the vibration measurements, it was established that the operating mark is UNALLOWED according to ISO 7919. The vibration diagnosis indicated a misalignment of the turbine’s shaft, but this offset is caused by the instability of the inferior radial bearing LRI, practically an increased mechanical looseness inside this bearing in the Y direction. The software tracks the relative vibrations at different turbine loads.

The software used for fault diagnostics is ProfiSignal Basic and ProfiSignal Vibro. Following the vibration measurements, it was established that the operating mark is UNALLOWED according to ISO 7919. The vibration diagnosis indicated a misalignment of the turbine’s shaft, but this offset is caused by the instability of the inferior radial bearing LRI, practically an increased mechanical looseness inside this bearing in the Y direction. The software tracks the relative vibrations at different turbine loads.

Following this vibration diagnosis, the data recommended that users check the fixation mode of bearing LRI onto the foundation, the state of the bushing, and also the mechanical looseness inside the bearing.

While checking bearing LRI, the repair team found that the nuts which adjusted the looseness in the bushing (Y direction) were all destroyed, as well as the thread on the bolts.

The absolute vibration measurements were taken with accelerometers using a portable analyzer, and the highest vibrations were recorded on the radial-axial bearing LRAx, while on the inferior radial bearing the vibrations amplitudes were small.

In conclusion, we can say that the machine diagnosis of those machines which have journal bearings in their assembly is done more precisely if the vibration measurements are done with proximity transducers and are acquired using the online mode, simultaneously on all the machine’s bearings. For this purpose, the Expert Vibro was ideal here and the customer was very satisfied post-installation.

Benefits

The advantages of a vibration monitoring system using the Delphin Expert Vibro system and the ProfiSignal software are as follows:

- Simultaneous monitoring of vibration amplitudes on all the bearings of the machine

- Extending the system for online monitoring and other technical parameters needed for machine diagnosis

- The creation of virtual channels to calculate looseness in the journal bearings

- The possibility of copying the measured data – amplitude 1x and phase 1x – to a balancing program that allows balancing–in situ, static and dynamic–of the rotors.

- Precession movement simulation of the shaft within the journal bearings.

- Data transmission and storage within the Expert Vibro device and on the hard disk of a computer.

- The ability to connect piezoelectric vibration transducers direct economical solution for a vibration monitoring system

- The increase in safety conditions and the prevention of machine damage with the help of the Alarm Management software and the Expert Vibro system’s analog and digital outputs.

For further information on Delphin Data Acquisition and Control Systems, and vibration monitoring systems or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.