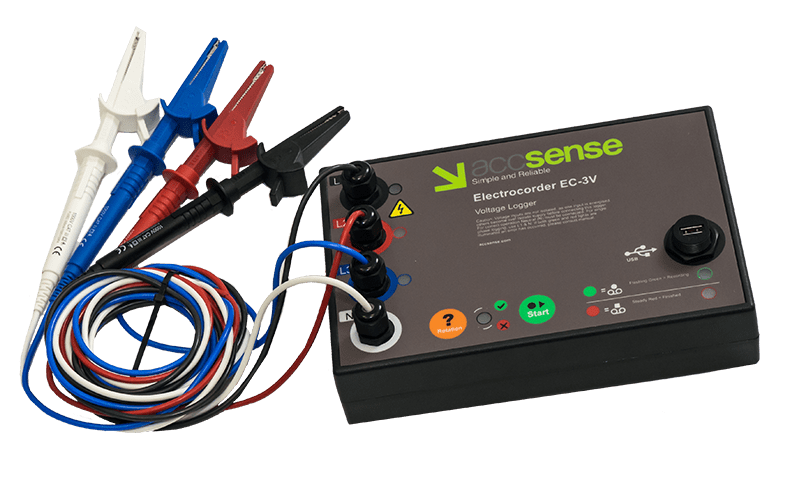

Accsense Electrocorder: Powerfully Measured

The average voltage supply from many national grids around the world is often higher than the ideal operating voltage for most electrical equipment from lighting to motors. A 230V linear appliance used on a 240V supply will take 4.3% more current. It will also consume almost 9% more electricity than at 230V. Sites fitted with a voltage optimization system often achieve reductions in the region of 5 to 15% for energy consumption, costs, and carbon emissions! For your own voltage optimization application, be sure to monitor and identify your present incoming voltage levels. Accsense Electrocorder data loggers are solutions that enable you to determine this for yourself.

The average voltage supply from many national grids around the world is often higher than the ideal operating voltage for most electrical equipment from lighting to motors. A 230V linear appliance used on a 240V supply will take 4.3% more current. It will also consume almost 9% more electricity than at 230V. Sites fitted with a voltage optimization system often achieve reductions in the region of 5 to 15% for energy consumption, costs, and carbon emissions! For your own voltage optimization application, be sure to monitor and identify your present incoming voltage levels. Accsense Electrocorder data loggers are solutions that enable you to determine this for yourself.

Single Phase voltage monitoring:

Accsense Electrocorder EC-1V

Single Phase voltage and current monitoring:

Accsense Electrocorder EC-2VA

Three Phase voltage monitoring:

Accsense Electrocorder EC-3V

Three Phase voltage and current monitoring:

Accsense Electrocorder EC-7VAR

Effects on Various Electrical Loads

A common misconception about voltage optimization is the assumption that a reduction in voltage will result in an increase in current. It’s also a misconception that the power consumed will remain constant. Most sites actually have a diversity of loads that will benefit to a greater or lesser extent, with energy savings aggregating across a site as a whole. But what about the benefit to the typical equipment at three-phase sites?

Three Phase AC Motors

The three-phase induction motor is one of the most common types of three-phase loads. It is used in many types of equipment including refrigeration, pumps, compressors, fans, conveyor drives, and lifting systems. Overvoltage results in flux saturation of the iron core, wasting energy through eddy currents and increased hysteresis losses. The drawing of excessive current results in excess heat output from copper losses. The additional stress of overvoltage on motors will decrease the motor’s lifetime.

However, avoiding overvoltage high enough to cause saturation does not reduce the motor’s running efficiency so you can realize substantial energy savings by reducing iron and copper losses. Motors designed for the nominal voltage should be able to cope with normal variation in voltage within the supply limits (+/-10%) without saturation–these motors are unlikely to be running in saturation, so savings are small.

Reducing voltage to an induction motor will slightly affect the motor speed as the slip will increase, but speed is mainly a function of the supply frequency and the number of poles. Motor efficiency is optimum at a reasonable load (typically 75%) and at the designed voltage, and will fall off slightly with small variations on either side of this voltage. Larger variations affect efficiency more heavily. Very lightly-loaded motors with a loading of around 25% and small motors benefit most from voltage reduction.

Motors driven by Variable Speed Drives will use the same power as before but may draw more current. It should be noted that with reduced stored energy in the DC Bus capacitors, they may be more vulnerable to power dips.

Switched Mode Power Supplies

Switched mode power supplies will use the same power as before, but will draw a slightly greater current to achieve this, along with slightly increased cable losses and a slight risk of the increased current tripping magnetic circuit breakers.

Lighting

If your lighting loads are in use for a high proportion of the time, you can realize large energy savings on your lighting equipment. After you’ve achieved voltage reduction, incandescent lighting will see a large decrease in power drawn as well as a large decrease in light output and an increase in lifetime.

You’ll find that other types of lighting can also benefit from improved power quality, including systems with resistive or reactive ballasts. Fluorescent & discharge lighting is more efficient than incandescent lighting. Fluorescent lighting with conventional magnetic ballasts will see reduced power consumption but also a reduced lumen output from the lamp. The fluorescent lamps on modern electronic ballasts will use approximately the same power and give the same light. Providing the same wattage at the reduced voltage will require a greater current and also increase cable losses. Lighting controllers and ballasts are responsible for generating high levels of harmonic distortion, which can be filtered with some types of voltage optimizers, therefore reducing the need for lighting controllers.

A common concern here is that some lighting will fail to turn on at lower voltages. The aim of voltage optimization is NOT just to reduce the voltage as far as possible, but rather to bring it to the service level voltage at which the equipment is designed to operate most efficiently.

Heating

Heaters will consume less power, but give out less heat. Note that thermostatically-controlled space or water heaters will consume less power while running, but will have to run for longer each hour to produce the required output, resulting in no savings.

Energy and Emission Savings

The energy savings you can achieve by voltage optimization are an aggregation of the improved efficiency of all your equipment across the site in response to the improvements in the power quality problems outlined above. It has been and continues to be a key technique for savings in energy consumption and consequently in carbon dioxide emissions.

Research conducted in Taiwan has suggested that, for an industrial supply with voltage reduction upstream of the transformer, there is a 0.241% decrease in energy consumption when the voltage is decreased by 1%, and an increase of 0.297% when the voltage is increased by 1%. This assumed a mixture of loads including 7% fluorescent lighting, 0.5% incandescent lighting, 12.5% single-phase air conditioners, 5% single-phase motors, 22.5% small 3-phase motors, and 52.5% large 3-phase motors. It’s likely that a modern installation would have less opportunity, with almost no incandescent lighting, partly high-frequency fluorescent lighting (no savings), some variable speed drives (no savings), and higher motor efficiencies (less waste to save). Other installations may not have a large number of small single-phase motors for air conditioning—still the findings are instructive.

You’ll probably find that the best potential for savings can be found with older lighting (incandescent or fluorescent) and discharge lighting with conventional control gear. Therefore older commercial and office premises are likely to have a better saving potential than modern buildings or industrial sites.

In summary, you can realize significant savings by using a datalogger to enact voltage optimization techniques, although as with any product you’re responsible for determining the likely savings in your own environment.

For further information on Accsense Electrocorders, and voltage optimization or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.