Automated Recording of Calibration Tasks Saves Time

CAS DataLoggers provided the data logging solution for calibration of test equipment at Total Calibration Solutions Inc., an Ohio-based calibration laboratory for test and measurement instruments throughout North America. As an ISO/IEC 17025:2005 and ANSI/ NCSL Z540-1-1994-accredited calibrator, Total Calibration is using the loggers not only to log and verify sensor calibration for their customers, but also to help customers with specific applications including monitoring a client’s warehouse. Total Solutions also offers NIST calibration and complies with FDA/FAA regulations as part of their instrument calibration procedure.

CAS DataLoggers provided the data logging solution for calibration of test equipment at Total Calibration Solutions Inc., an Ohio-based calibration laboratory for test and measurement instruments throughout North America. As an ISO/IEC 17025:2005 and ANSI/ NCSL Z540-1-1994-accredited calibrator, Total Calibration is using the loggers not only to log and verify sensor calibration for their customers, but also to help customers with specific applications including monitoring a client’s warehouse. Total Solutions also offers NIST calibration and complies with FDA/FAA regulations as part of their instrument calibration procedure.

General Manager Mark Hanson explains, “We use several different types of data loggers, both individually and in groups, to provide NIST-traceable calibration services. Additionally we assist customers utilizing loggers for internal projects. An example of this would be warehouse temperature and humidity validation. This is required to meet certain FDA guidelines for product storage.”

Installation

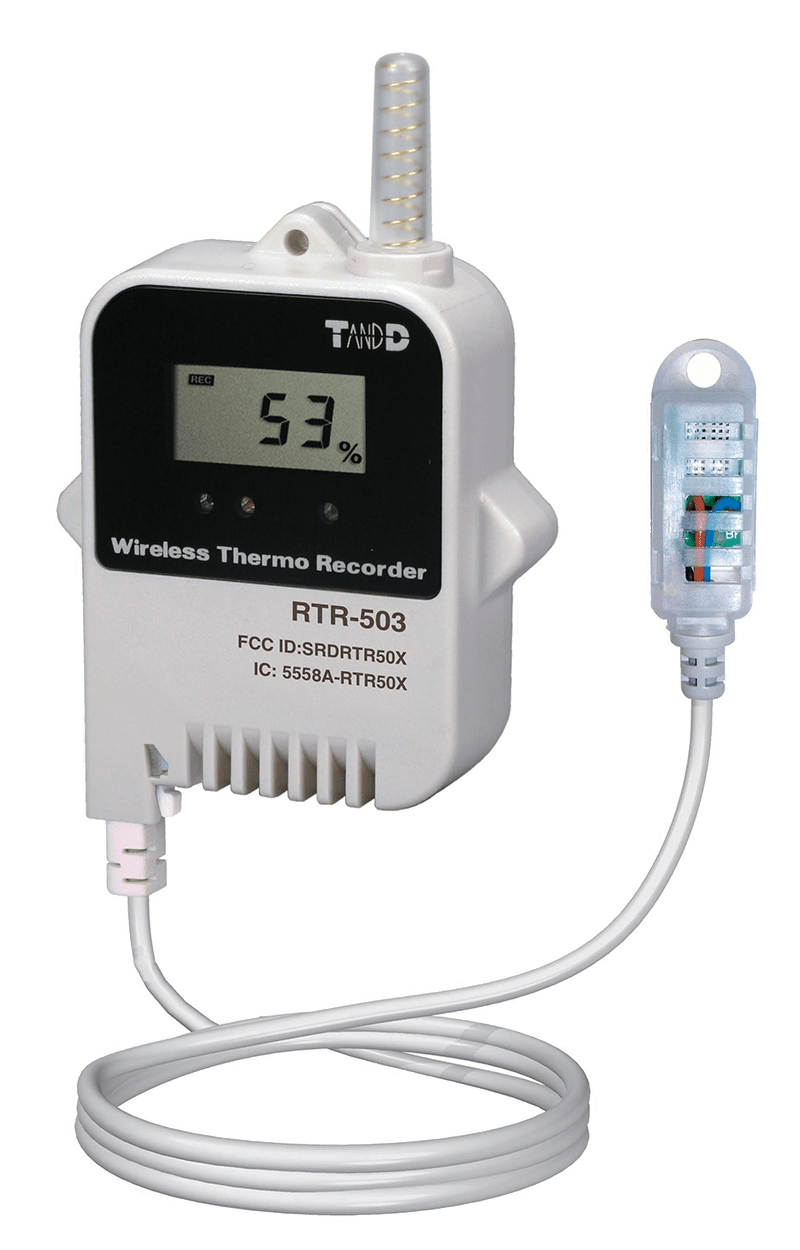

Total Calibration uses T&D RTR-500 Series wireless data loggers to take automated temperature and humidity measurements. This includes T&D’s RTR-503 Wireless Temperature and Humidity loggers and RTR-500DC Wireless Handheld Data Collector.

Mark continues, “We have multiple calibration chambers used to calibrate our customers’ sensors. he most utilized chamber in which we log data is about 24x24x36 square inches. We also have larger chambers up to 36x36x48 square inches from top to bottom.”

Mark continues, “We have multiple calibration chambers used to calibrate our customers’ sensors. he most utilized chamber in which we log data is about 24x24x36 square inches. We also have larger chambers up to 36x36x48 square inches from top to bottom.”

“The RTR-503 is currently deployed inside our main calibration chamber. Previously to sourcing T&D, we used little USB loggers to record the temperature and RH data with 10 or 15 loggers to a chamber, for example placing 5 on the top rack, 5 on the bottom rack. After running each test, we had to go through the labor of downloading all of the dates from each one for comparison. Now we simply place a wireless logger inside, and collect data live to produce an Environmental Chamber Survey for our customers.”

How Has Data Logging Helped Your Calibration House?

“Using the loggers has helped us to automate many calibration of test equipment tasks.

We use the temperature and humidity data logger to monitor incubators for our customers. I like T&D’s automated recording capability so I can leave the logger to record while running a calibration cycle in the incubators.

For example we have a humidity generator that cycles through certain humidity set points throughout the day, so with the automated logger we can just let it record. Afterward we view the time-stamped readings and then present all our calibration data to the customer.

I feel that for many of these types of applications, people should be using loggers instead of analog and display-only devices. It’s just too time-consuming to check readings manually so this product is really a time-saver.”

Warehouse Data Collection

“One of our customers who owns a warehouse really loves T&D too. We’re continually monitoring the interior temperature at several points. In most cases I collect the data from several loggers using the RTR-500DC handheld data collector. It’s neat because the collector lets you specify which remote units you want to collect data from, then it pulls all the temperature data via USB, or you can view data from the collector’s LCD one at a time.

The T&D loggers are completely wireless and we can set groups, locations etc., and then just pull the data all at once. You don’t need an Ethernet connection. We do use Ethernet data loggers in other HVAC setups, and they’re great for certain applications and utilizing Wi-Fi with T&D, you don’t have to wire everything to get the data, so we like doing it this way.”

Configuration & Setup Software

Lab Manager Josh Hanson handled setup of the T&D units for monitoring the customer’s warehouse and has also calibrated a sensor grid for them in the main calibration chamber. “It was pretty easy to pick up the software; it didn’t take me more than 15 minutes to set it up.”

“T&D is especially neat for us when it comes to projects like our warehouse application. The software lets us name each logger and color-code different areas, so the north wall is colored blue, the west portion of the warehouse is picked out in green, etc.”

Would You Recommend T&D Wireless Products to Other Calibrators?

Mark Hanson responds, “Yes, certainly. These T&D units are nice in a calibration sense. We like the ease of use of the data collector and the software, and the RTR-503’s accuracy is surprisingly good. Right out of the box the accuracy is good and after testing we didn’t have to make any adjustments. T&D is competitively-priced so you don’t have to spend a fortune for a true 2% logger.”

For more information on T&D Wireless Data Loggers, additional T&D products, calibration of test equipment or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.