Accsense Covers All Monitoring Points and Values in Complex Setup

CAS DataLoggers provided an automated monitoring and alarm system for an in vitro fertilization clinic which needed a wireless setup to provide automated temperature, humidity and CO2 monitoring for double-stack incubators. These incubators were used as part of the embryonic IVF program. Staff needs to ensure that the incubators maintained a constant temperature of 37oC (99oF) and relative humidity of 99%. Each incubator is also equipped with an external CO2 tank which lasts about a month. The incubator controllers have internal sensors to determine the CO2 levels inside and keep them within an acceptable range (about 5% concentration). However, sensor accuracy is vulnerable to temperature and humidity fluctuations within the incubators caused by opening the doors. Therefore this complex setup required an automatic incubator monitoring system to monitor and alarm temperature, humidity, and CO2 in real time to alert staff of levels outside of the acceptable range and help prevent any losses.

CAS DataLoggers provided an automated monitoring and alarm system for an in vitro fertilization clinic which needed a wireless setup to provide automated temperature, humidity and CO2 monitoring for double-stack incubators. These incubators were used as part of the embryonic IVF program. Staff needs to ensure that the incubators maintained a constant temperature of 37oC (99oF) and relative humidity of 99%. Each incubator is also equipped with an external CO2 tank which lasts about a month. The incubator controllers have internal sensors to determine the CO2 levels inside and keep them within an acceptable range (about 5% concentration). However, sensor accuracy is vulnerable to temperature and humidity fluctuations within the incubators caused by opening the doors. Therefore this complex setup required an automatic incubator monitoring system to monitor and alarm temperature, humidity, and CO2 in real time to alert staff of levels outside of the acceptable range and help prevent any losses.

Installation

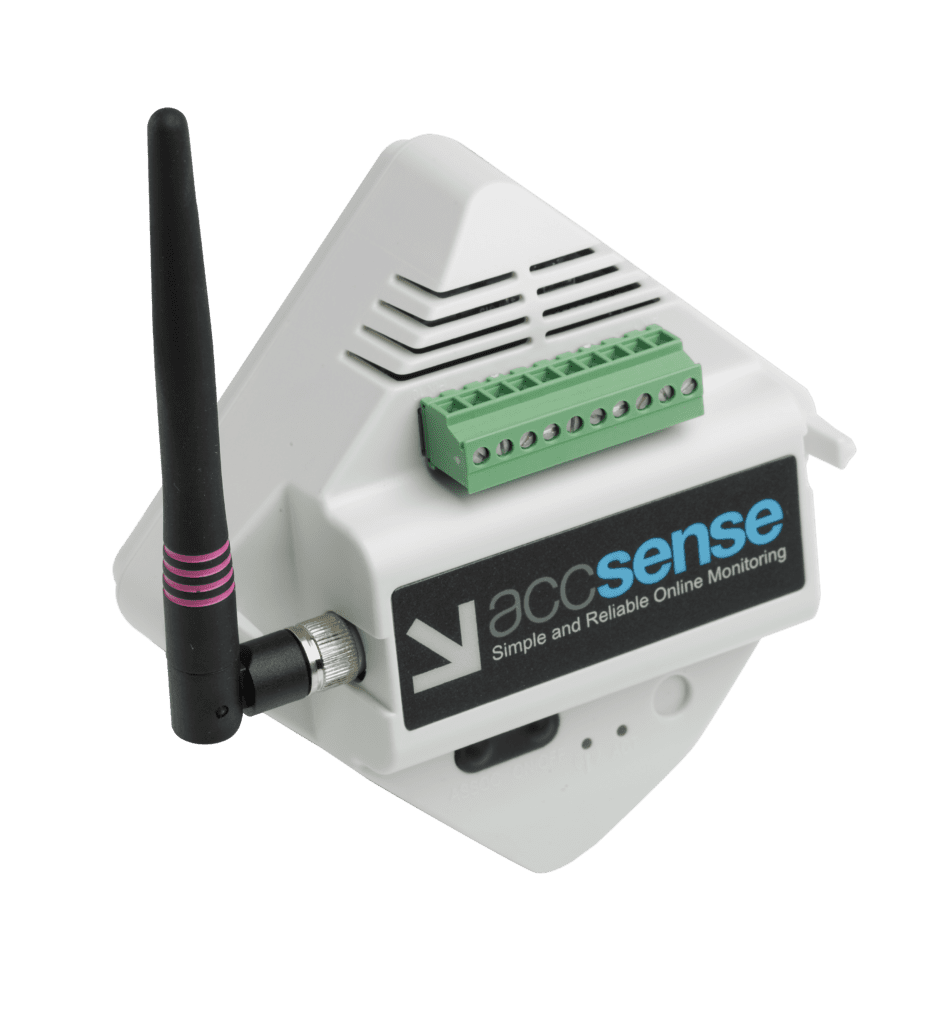

After taking their call, CAS DataLoggers visited the clinic and installed an Accsense monitoring system consisting of 3 Accsense A1-10 Wireless Current Data Loggers and a gateway. Each data logging pod was capable of accepting 6, 4-20mA inputs which were connected to 2 temperature and humidity sensors along with 2 CO2 sensors allowing a single unit to monitor all three parameters for both incubators in the stack.

The 3 pods communicated with an Accsense B1-06 Wireless Data Logger Gateway which aggregated all of the data and uploaded it via the network to the Accsense Cloud server.

Usage

The wireless pods utilize Zigbee networking to allow a communications range up to 90’ indoors and which also allows them to act as repeaters to relay data from other pods. The wireless gateway uses built-in 10/100BaseT Ethernet and supports DHCP and static IP addressing to simplify integration in any type of network. In the event the gateway can’t be reached, individual pods store up to 255 data points until the wireless connection is restored. The gateway’s also incorporating a sample data buffer to eliminate data loss in the case of a network outage and further ensure continuous monitoring.

In addition to the analog inputs, each logger offers 2 digital inputs to enable alarms to be generated by an external contact closure, for example, if the incubator controller goes into alarm mode. Within the Accsense Cloud software, users can configure alarms limits for the temperature, humidity, and CO2 level to send email, pager or phone warnings to multiple designees whenever an alarm triggers.

In addition to the analog inputs, each logger offers 2 digital inputs to enable alarms to be generated by an external contact closure, for example, if the incubator controller goes into alarm mode. Within the Accsense Cloud software, users can configure alarms limits for the temperature, humidity, and CO2 level to send email, pager or phone warnings to multiple designees whenever an alarm triggers.

Cloud-based data storage and reporting enable effective monitoring as each pod measures and logs data, giving staff the ability to view and remotely access data in real-time. The gateway sends all this data to the secure Accsense cloud server. From this server, the data can be downloaded as a CSV file for use with many database applications.

Additionally, the online Accsense website gives instant access to charts showing all measurement history with ranges as narrow as 5 minutes or as wide as 90 days. The site also features a dashboard showing the most recent measurements from all sensor pods and alarm status. Clinic personnel can retrieve all readings for offline analysis, log in to access reports and graphs, and can modify the system setup from anywhere they’re connected to the Internet for an effective incubator monitoring system.

Benefits

Now the clinic relies on an Accsense monitoring system to notify employees when any of the incubator environments are drifting out of range. Whenever this happens, the system makes alarm phone calls until staff designees respond and take safety measures. Likewise, the system sends all readings to the cloud so that regulators have proof that best practices were followed. Accsense was particularly cost-effective for this incubator monitoring application, covering 6 monitoring points and 3 separate values with just 3 data loggers and a gateway.

For more information on our Accsense systems for clinics, hospitals, and clean rooms, or for cost-effective incubator monitoring systems, contact a CAS Data Logger Application Specialist at (800) 956-4437 or request more information.